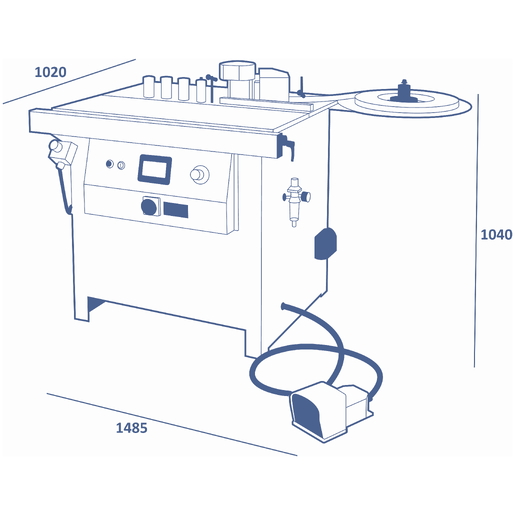

e 20 manual edge bander for straight and shaped panels

A$13,475.00

(Price does not include taxes, shipping and installation)

4,3” touch screen with advanced functions complete with:

* Adjustment of the edge feed speed from 3 to 8 m/min

* Management of manual work modes, programmed cutting and measure of the panel perimeter

* Automatic calculation of the required edge length with reference to the most common geometries

Teflon-coated hot melt glue pot installed underneath the worktable to ensure a continuous glue recirculation and avoid its overheating. Powerful heating system for an immediate use with timed stand-by

Powered pressure roller to facilitate the panel feed during

- High rigidity and stability steel monoblock base

- Anti-scratch phenolic multilayer work table with modular holes complete with supports for the panels support to guarantee no risk of damaging the moving panels

- Front extension for the support of large dimensions panels

- Shear device for rolled edges complete with 780 mm (30.69”) coil-holder plate

- Glue application of edging material by means of a powered glue spreading roller

- 3-roller outfeed fence for a better gluing quality on large dimensioned straight

- Wheels for an easy machine movement

- Emergency pushbutton located on the front machine side, padlockable main switch, Stabilised power supply for auxiliary circuit 24V in direct current.

Machine configuration

- 780 mm coil-holder plate

- Adjustable tilting table from 0 to 45°

- Infeed fence for linear panels

- 3-roller outfeed fence

- Front extension for the support of large dimensions panels

- Wheels to allow machine movement

Technical data

| Thickness of pre-cut edges in strips | mm | 0,4 – 3 (0.19” - 0.12”) |

| Thickness of edges with shear device: (50 mm height) (45 mm height) |

|

0,4 - 2,5 (1/64” – 3/32”) 0,4 – 3 (1/64” – 1/8”)

|

| Edges height | mm (in) | 10 – 84 0.39” – 3.31” |

| Panels thickness | mm (in) | 8 – 80 0.31” - 3.12” |

| Minimum panel width | mm (in)

| 50 (1.94”) |

| Minimum panel length to be applied | mm (in) | 290 (11 13/32”) |

| Minimum internal radius with 0,4 mm edge thickness (concave profile) | mm (in) | 25 (0.94”) |

| Minimum external radius with 0,4 mm edge thickness (convex profile) |

|

|

| Feed speeds | m/min (ft/min) | 3-4-5-6-7-8 (10-13-16-20-23-26) |

| MINIMUM INSTALLATION REQUIREMENTS |

|

|

| Average compressed air consumption | l/min | 10 (0.37”) |

| Installed motor power | kW | 6,9 |

| Operating temperature | °C (°F) | 140 -220 ( 284 -428)

|

| Voltage /Frequency |

| 400EU / 50Hz |