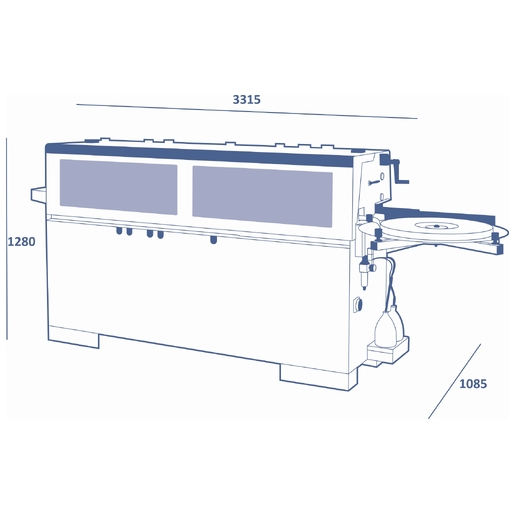

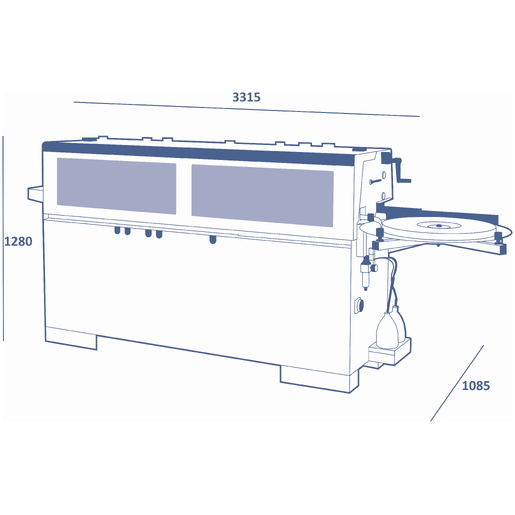

me 35t Automatic edge bander with pre-milling unit

Ease-of-use with all inclusive equipment: me 35, with gluing of the panel edge, also with edging solid wood strips up to 5 mm thickness, offers the “very best” performance in edge banders at this level.

The features, coupled to its ease-of-use, makes it the perfect edge bander for small woodworking, furniture and panel processing companies.

me 35. Further enhanced compared to its predecessor with the new end cutting-rounding unit. This new unit allows further processing, saving a substantial amount of time with an ease of processing.

This technological solution is unique in its category, where such operations are normally a feature of more expensive and higher level machinery.

Designed for a perfect finish

A new combined end cutting-rounding unit with rigid structure for unique quality processing in its market segment. Now the rounding process is available for all workshops.

Brillant idea

The optional end-cutting unit with "Radius" allows to make a radius on the corners of the edged panel without the need of the operator to have to finish by hand at a later stage: brillant idea to a finished product of high quality.

Machining units with automatic on/off system and multi-radius tools

High performance and rapid setting thanks to the new automatic system with pneumatic on/off controlled by the machine NC for trimming unit, edge scraping unit and glue scraping unit.

Flexibility and accuracy to perform a radius on the edge with the multi-radius tools, available for trimming unit and edge scraping unit: possibility of machining different edge thicknesses with automatic set up.

| TECHNICAL DATA | ||

| Work table dimensions | mm | 3000 x 525 |

| Min. ÷ max. thickness of rolled edges | mm | 0,4 ÷ 3 |

| Max. thickness of edges in strips | mm | 5 |

| Min. ÷ max. panel height | mm | 8 ÷ 50 |

| Min. panel length/width | mm | 190/110 |

| Min. panel length/width with end cutting/rounding unit | mm | 120/110 |

| Feed speed | m/min | 7 |