me 40tr With nesting

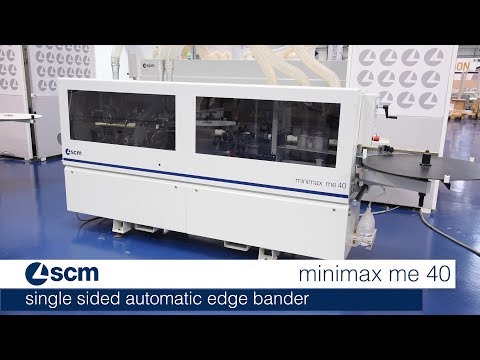

High productivity edge bander with high quality performance.

It allows to obtain high quality finished products, without further processing, allowing a considerable saving of time and increasing ease of processing. It is confirmed as the most accessorizable machine in its technological range, with an excellent quality / price ratio.

This edgebander increases productivity with the feed track of the panel brought to a speed of 9 m/min and it guarantees high quality standards in processing thanks to the possibility of working with polyurethane glue, perform grooves, all being extremely easy to use.

Machining units with automatic on/off system and multi-radius tools

High performance and rapid setting thanks to the new automatic system with pneumatic on/off controlled by the machine NC for trimming unit, edge scraping unit and glue scraping unit. Flexibility and accuracy to perform a radius on the edge with the multi-radius tools, available for trimming unit and edge scraping unit: possibility of machining different edge thicknesses with automatic set up.

Technologically advanced solutions

The rounding unit carries out the rounding of thin and thick edges up to 3 mm, for the best panel finish quality.

Brillant idea

The optional end-cutting unit with "Radius" allows to make a radius on the corners of the edged panel without the need of the operator to have to finish by hand at a later stage: brillant idea to a finished product of high quality.

| TECHNICAL DATA | ||

| Work table dimensions | mm | 3465 x 710 |

| Min. ÷ max. thickness of rolled edges | mm | 0,4 ÷ 3 |

| Max. thickness of edges in strips | mm | 5 |

| Min. ÷ max. panel height | mm | 8 ÷ 50 |

| Min. panel length/width | mm | 190/110 |

| Feed speed | m/min | 9 |