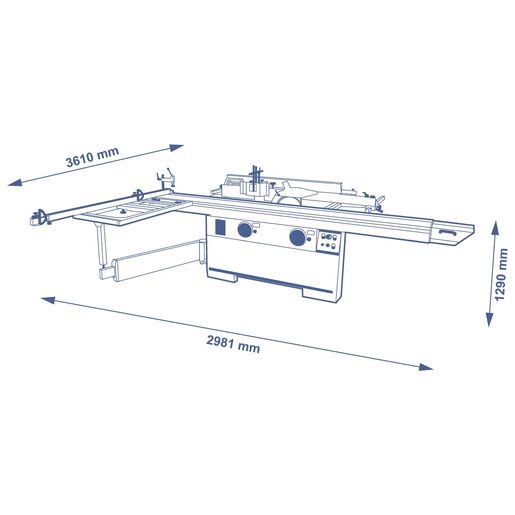

minimax cu 410e Universal combined machine

A$31,350.00

(Price does not include taxes, shipping and installation)

The first distinctive feature of the cu 410e universal combination machine is the ease of use guaranteed by the system of surfacing worktable opening toward the inside of the machine. This combination machine is also equipped with anodized-extruded guides with support and rapid locking and an effective feeding system for the planer. These features make this machine easy-to-use for any type of machining. Another amazing feature of this machine is its maximum flexibility when using the cutters, with the spindle moulder unit equipped with various speeds. The machine is equipped with a spindle moulder hood with micrometric adjustment, very useful for moulding work.

*Photos may include optional equipment. Please verify availability and compatibility under Product Details and Specs.

Incredible cutting thanks to the saw unit with a blade (not included) that has a maximum diameter of 315 mm with the scoring blade installed

Optimal support also to larger pieces, with the sliding table 360 mm wide. The guides are secured with a procedure of aluminum riveting, so that to ensure an exceptional precision and smoothness

The planer infeed roller has a helicoidal profile to guarantee firm and constant work piece feed, while the outfeed roller, in sandblasted steel, maintains the perfect post-processing finishing

Maximum stability and rigidity in all working conditions, thanks to a large spindle moulder column made entirely of cast iron

SCM Thundercut App for mobile devices: optimizer/sequencer even for not skilled workers

- The saw unit closed loop structure is made of a heavy cast iron and is supported firmly under the table by two lateral supports in a crescent shape: these solutions give strength and rigidity, guaranteeing perfect cutting results

- The scoring blade is adjustable from the outside without tools and allows fast and accurate positioning with no play

- The sliding table ensures a top quality precision with a smooth and silent action, a self-cleaning dustproof system, and a long lasting accuracy with no adjustments required

- Scoring unit with independent motor complete with blade, with external setting up

- Panel loading is easy on the large squaring frame with an idle roller at the end. The telescopic squaring fence has two reversible stops so to have precise references on both sides of it

- The “Xylent” spiralknives cutter block gives an exceptional finish with reduced noise during machining thus to provide a more comfortable working environment

- For an impeccable finishing, the pressure of the thicknesser feed rollers can be adjusted according to the type of wood machined

- For the saw and the surfacing planer the machine has professional fences designed to be easy to remove and to allow a rapid changeover from one type of operation to another

- The 4 standard speeds of the shaper are ideal for any type of machining, from shaping to routing

- Anodized aluminium tables for spindle moulder fence

- The shaper has a tiltable spindle moulder 90° ÷ 45° for the maximum versatility and has an handwheel on the front of the machine, with numerical readout, for easy unit positioning

- The shaper spindle is surrounded by a cast iron “cup” to protect the internal mechanical components from shavings and sawdust

- Spindle moulder with Interchangeable spindle for a very quick spindle substitution.

- Spare spindle for router bits complete with 12 mm clamp

- Wheels for an easy machine movement

TECHNICAL FEATURES | ||

Planer: | ||

Useful working width | [mm] | 410 |

Cutter block diameter | [mm] | 87 |

Max. stock removal | [mm] | 5 |

Surfacing tables total length | [mm] | 2000 |

Thicknessing table dimensions | [mm] | 423 x 775 |

Feed speeds on thicknesser | [m/min] | 6/12 |

Min. ÷ max. working height on thicknesser | [mm] | 3 ÷ 230 |

Min. working length on thicknesser | [mm] | 160 |

Circular saw: | ||

Cast iron saw-spindle moulder worktable dim. | [mm] | 1250 x 430 |

Blades tilting | 90° ÷ 45° | |

Max. saw blade Ø with scoring blade installed | [mm] | 315 |

Max. saw blade projection from table at 90°/45° | [mm] | 100/71 |

Max. squaring stroke | [mm] | 2600 |

Cutting width on parallel fence | [mm] | 1050 |

Spindle moulder: | ||

Spindle mouder shaft | [mm] | 30 |

Max. useful spindle length | [mm] | 125* |

Spindle moulder speeds | [rpm] | 3500/6000 |

Max. tool diameter when profiling | [mm] | 210 |

Max. Ø of tool lowered under the table at 90° | [mm] | 240 |

Other technical features: | ||

3 three-phase motors 5kW (6,6hp) 50Hz | [kW/hp/Hz] | 5/6,6/50 |

Exhaust outlets diameter | [mm] | 120 |

Installation requirements | ||

Section of electrical cable | [mm2] | 4 |

Power absorption | [A] | 13 |

CE version voltage - frequency | 400eu - 50Hz |