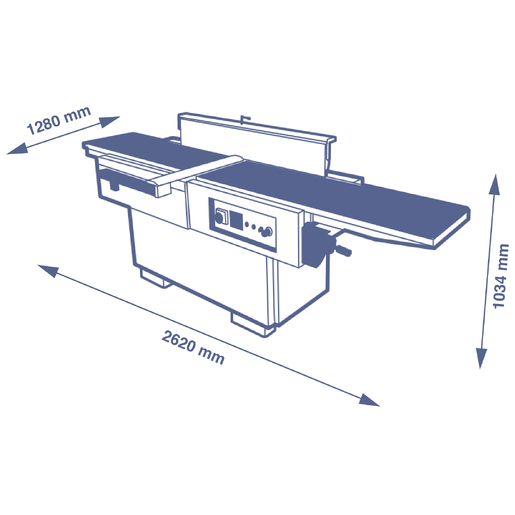

nova f 410 Surface planer

(Taxes not included)

The nova f 410 is a jointer machine whose accuracy lasts a lifetime and without noise with the system on connecting rods.

The system guarantees the maximum movement fluidity and avoids deformations of the work table. This guarantees maximum stability, reliability and ergonomics. This is not the only feature loved by woodworkers. The total absence of vibration thanks to the large worktables made from ribbed cast-iron guarantee precision and a very good quality of the results on the processed workpieces.

*Photos may include optional equipment. Please verify availability and compatibility under Product Details and Specs.

Available 3

Item ready for delivery

The movement of the infeed table by means of a parallelogram kinetic mechanism always gives the same distance between the cutterblock and the table assuring constant planarity over time.

High rigid fence with a smooth movement thanks to the central locking on round bar. The graduated scale facilitates the operator in positioning the guide to the required tilting.

Total absence of vibration thanks to the large worktables made from ribbed cast-iron.

The “Xylent” spiralknives cutter block gives an exceptional finish with reduced noise during machining thus to provide a more comfortable working environment.

- The “Xylent” cutter block also improves the dust extraction due to the production of very small chips

- Each cutter of the “Xylent” block has 4 tips which can be rotated into the cutting position when worn, therefore increasing the knives production life before they require replacement

*Does not include power cable

MACHINE CONFIGURATION

(Options and accessories included with this machine)

- Additional overturning fence

- "Xylent" spiralknife cutterblock with 3 series of knife

- 10 spare inserts kit (15x15x2,5) for Xylent spindle

| TECHNICAL FEATURES | ||

Working width | mm (in) | 410 (16.12”) |

| Total length of worktables | mm (in) | 2610 (102.75”) |

| Infeed table length | mm (in) | 1450 (57.06”) |

| Outfeed table length | mm (in) | 1160 (45.69”) |

| Cutterblock diameter | mm (in) | 120 (4.75”) |

| Cutterblock speed | rpm | 5000 |

| Aluminium surface fence | mm (in) | 1200 x 190 (4.75 x 3.56”) |

| Max. stock removal | mm (in) | 8 (0.31”) |

| Other technical features: | ||

| Three-phase motor | 6kW (8hp) 60Hz | |

| Exhaust outlets diameter | mm (in) | 120 (4.75”) |

| MINIMUM INSTALLATION REQUIREMENTS | ||

| Power absorption | [A] | 24 |

| Voltage frequency | 600V 60Hz |

For any questions concerning delivery, please contact eshopsupportca@scmgroup.com

To ensure a clear and hassle-free purchasing experience, below are the weight and dimensions of the packaged machine at the time of delivery:

| Dimensions | ||

| Lenght | cm (in) | 265 (105) |

| Width | cm (in) | 115 (46) |

| Height | cm (in) | 118 (47 ) |

| Weight | kg (lb) | 743 (1639) |

Before completing the purchase, the customer will choose the following delivery option:

Dedicated Courier Delivery (Incoterm DAP - Delivered at Place)

By selecting this option, SCM will entrust delivery to a specialized carrier, ensuring safe transportation handled by professionals. The service includes:

- Phone advance notice prior to delivery

Important: Due to the size of the machine, unloading from the truck is the responsibility of the customer. A forklift or appropriate equipment will be required to safely complete the unloading process. Internal transportation and placement within the premises are not included.

If the machine is purchased with installation service, after the order is completed, SCM Service or an authorized center will contact the customer to coordinate: the date of installation, equipment needed, and documentation required for installation.

SCM Group Canada is not responsible for any damages, injuries, or losses resulting from improper installation, unsafe or incorrect use of the machine, failure to follow the manufacturer’s guidelines, or any modifications made by the customer or third parties.

Customers who choose to opt out of professional installation assume full responsibility for ensuring that the machine is installed and operated in strict accordance with the provided instructions and safety standards. If you have not received the user manual, please contact servicecanada@scmgroup.com with the machine’s serial number to obtain it before installation and use.

SCM Group Canada disclaims all liability for any accidents, malfunctions, or consequential damages resulting from non-compliance with these guidelines.

Installation & Warranty Activation

If installation is not included in your purchase and you would like to have the machine installed by our technicians, please contact servicecanada@scmgroup.com or call 437-335-6781 (Monday to Friday, 7:30 AM – 4:30 PM EST) for assistance.

If SCM installation is not required, you must complete and submit the warranty activation form (VICA) to servicecanada@scmgroup.com within 10 business days from the machine’s delivery date. The form will be provided with the purchase order confirmation or can be requested by contacting us. Failure to submit the form on time may result in the warranty being voided.