profiset 60ep Automatic planer and thoroughfeed moulder

Starting from {0}

(Price does not include taxes, shipping and installation)

The profiset 60ep is an 5 spindles Automatic planer and throughfeed moulder with possibility to preset the profiling on the top horizontal spindle. The SCM solution "Set-up" allows a simple and rapid set up when changing tools as it has the minimum tool diameter as only reference. It is enough a single adjustment to position all elements (tool, working height, front and rear pressers, feeding rollers) with no idle retooling times . For an absolute ergonomics and safety, all controls for the working units set-up are situated on the machine front side and have mechanical readouts with decimal precision of the working section.

*Photos may include optional equipment. Please verify availability and compatibility under Product Details and Specs.

With the Easy Plus electronic control it is possible to easily and comfortably set and monitor the machine through the 7” LCD colour display at 16:9 resolution. Some of its features:

• automatic control of left vertical spindle and upper horizontal spindle positioning

• feed speed selection

• tools database with visualisation of tools picture

• programs database with visualisation of tools picture and position

For an absolute ergonomics and safety, all controls for the working units set-up are situated on the machine front side and have mechanical readouts with decimal precision of the working section

The SCM solution "Set-up" allows a simple and rapid set up when changing tools as it has the minimum tool diameter as only reference. It is enough a single adjustment to position all elements (tool, working height, front and rear pressers, feeding rollers) with no idle retooling times

Productivity and improved finishing are granted by the optimum machine’s feeding thanks to:

• gears box drive and cardan joints technology

• pneumatic working pressure on the feed rollers

• inverter for the stepless speed adjustment from 5 to 25 m/min

The use of the reference engraver on the first lower spindle ensures an optimal reference guide for the workpiece to be machined allowing to obtain a perfect straightening

- The idle roller placed on the outfeed table, typical feature of industrial level machines, guarantees a very effective feeding and the best finishing

- The infeed table and the infeed right guide have a transversal adjustment by means of a parallelogram system which ensures an absolute precision

- The manual pump for the worktable lubrication positioned in the operator area facilitates its use, assuring always the best smooth movement of the workpiece

- The vertical spindles allow a profiling capacity of up to 40 mm and have an axial adjustment of 40 mm to manage more profiles

- For the maximum versatility, the machine is equipped with a kit to enable the profiling of the top horizontal spindle that includes also two mechanical readouts with decimal precision

- The 2500 mm infeed worktable allows to machine very long workpieces

- The machine comes with the ease-to-use tool diameter measurement device “Preset 25” which has a centesimal accuracy

- The safety integral cabin ensures low emission of noise and dust guaranteeing a full view of the machine at the same time.

*Does not include power cable

MACHINE CONFIGURATION

(Options and accessories included with this machine)

- 220 volt version

- Automatic star-delta start for motors

- Increased motor powers: - comp. 5

- Brake for 4 motors - composition 5

- Kit for enabling profiling with the top spindle

- Second flanged feed roller opposite left vertical spindle

- Feed unit - Composition 5

- Vertical pressure with idle roller placed in front of right spindle

- 2500mm infeed worktable

- Kit for min. working width from 25 to 15 mm

- PRESET 25: tool diameter measurement device

TECHNICAL FEATURES |

| |

Minimum working width (finished section) | mm | 15 |

Maximum working width (finished section) | mm | 230 |

Minimum working height (finished section) | mm | 10 |

Maximum working height (finished section) | mm | 120 |

Minimum length of single component - comp.5 | mm | 420 |

Variable feed speed with inverter | m/min | 5 ÷ 25 |

Feed motor power | 3 kW (4 Hp) | |

Planer spindle motor power | 5,5 kW (7,5 Hp) | |

Vertical spindles motor power (single) | 11 kW (15 Hp) | |

Top horizontal spindle motor power | 7,5 kW (10 Hp) | |

Bottom horizontal spindle motor power-Comp.5 | 5,5 kW (7,5 Hp) | |

Spindles speed | rpm | 6.000 |

Spindles diameter | mm | 40 |

Vertical spindles length | mm | 140 |

Horizontal spindles length | mm | 250 |

Axial adjustment of vertical spindles with respect to the worktable | mm | 40 |

Axial adjustment of horizontal spindles with respect to the right fence | mm | 40 |

Min./max. tool diameter on surface planer | mm | 120 – 140 |

Min./max. tool diameter on vertical spindles | mm | 100 – 180 |

Max. profiling capacity on vertical spindles | mm | 40 |

Min./max. tool diameter on top horizontal spindle | mm | 100 - 180 |

Min./max. tool diameter on 2nd bottom horizontal spindles | mm | 100 – 180 |

Profiling capacity with tool 180 mm on 2nd bottom horizontal spindles | mm | 15 |

Feed rollers diameter | mm | 140 |

Infeed table length | mm | 2.500 |

Rapid adjustment of infeed table and fence | mm | 10 |

USA version Voltage-Frequency |

| 230V-60Hz |

For any questions concerning delivery, please contact eshopsupportus@scmgroup.com

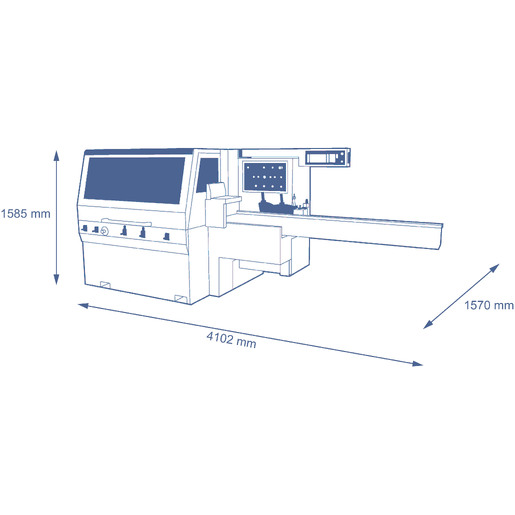

To ensure a clear and hassle-free purchasing experience, below are the weight and dimensions of the packaged machine at the time of delivery:

| Dimensions | ||

| Lenght | in | 162 |

| Width | in | 63 |

| Height | in | 71 |

| Weight | lb | 4741 |

Before completing the purchase, the customer can choose between two delivery options:

1 - Pickup from Our Warehouse (Incoterm EXW - Ex Works)

The machine can be picked up personally from our warehouses. Prior to purchase, verify in which locations this unit is available.

2 - Delivery by Dedicated Freight Carrier (Incoterm DAP - Delivered at Place)

By selecting this option, SCM will entrust the delivery to a specialized freight carrier, ensuring secure transport managed by professionals. The service includes:

- Advance phone notice before delivery

Important: Due to the size of the machine, unloading from the truck is the customer’s responsibility. A forklift or appropriate equipment will be required to safely complete the unloading process. Internal transport and positioning inside the premises are not included.

If the machine is purchased with the installation service, after the order is completed, SCM Service or an authorized center will contact the customer to coordinate: the installation date, the necessary equipment, he required documentation for installation.

SCM Group US is not responsible for any damages, injuries, or losses resulting from improper installation, unsafe or incorrect use of the machine, failure to follow the manufacturer’s guidelines, or any modifications made by the customer or third parties.

Customers who choose to opt out of professional installation assume full responsibility for ensuring that the machine is installed and operated in strict accordance with the provided instructions and safety standards. If you have not received the user manual, please contact us with the machine’s serial number to obtain it before installation and use.

SCM Group US disclaims all liability for any accidents, malfunctions, or consequential damages resulting from non-compliance with these guidelines.

Installation & Warranty Activation

If installation is not included in your purchase and you would like to have the machine installed by our technicians, please contact us.

If SCM installation is not required, you must complete and submit the warranty activation form (VICA) within 10 business days from the machine’s delivery date. The form will be provided with the purchase order confirmation or can be requested by contacting us. Failure to submit the form on time may result in the warranty being voided.

For any further information or assistance, please feel free to contact us.