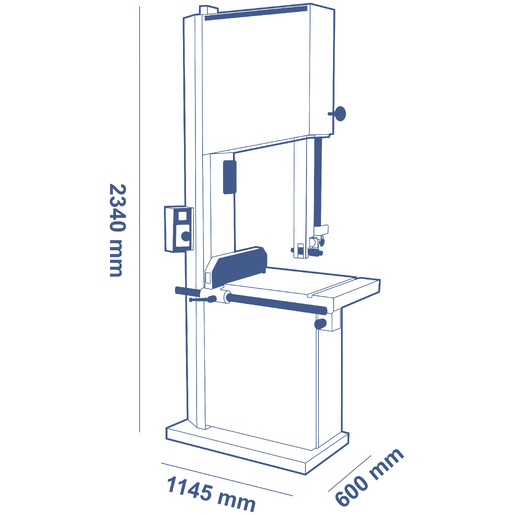

formula s 640p Band saw - 3ph

(Price does not include taxes, shipping and installation)

The s 640p formula band saw is equipped with a cast iron work table as well very thick cast iron wheels running on sealed for life ball bearings

This has a positive effect on the stability, precision and therefore reliability of the machine.

The top and bottom high precision blade guides ensure a perfect result when carrying out the straight and tilted cuts on wooden, plastic or aluminum materials

The dimensions of this machine are larger than the previous model (formula s 540p), this allows machining on larger materials.

*Photos may include optional equipment. Please verify availability and compatibility under Product Details and Specs.

Solidity and sturdiness

Very thick, cast iron wheels, as well as the worktable, running on sealed for life ball bearings.

Safety first

Total safety machining with telescopic protections with rackwork to the blade.

Perfect results

A perfect cut result is assured by the top and bottom high precision blade guides. Practical machines suitable also to perform straight and tilted cuts on wood, plastic and aluminum.

- Cast-iron squaring fence for maximum stability and cutting repeatability

- Rack and pinion lifting system of the guide unit for a fast and safe setup

- Saw blade tensioning indicator that guarantees immediate and continuous control of the value

- Cast-iron work table with lapped surface for maximum smoothness of the piece

- Full disc cast iron wheels to keep the blade speed constant during machining

- Top and bottom blade guide with ball bearings to minimize lateral movements of the blade and therefore increase the precision of the cut

- Cleaning brush on bottom wheel to reduce the wheel wear

- Mobility Kit

*Does not include power cable

MACHINE CONFIGURATION

(Options and accessories included with this machine)

- Wheels for machine movement

- Three-phase motor S1 - 6,7kW (9hp) 60Hz (only for USA version)

| TECHNICAL FEATURES | ||

| Worktable dimensions | m/min | 600 x 885 (23.62” x 34.81”) |

| Cast iron saw wheels diam. | mm(in) | 640 (25.19”) |

| Saw wheels width | mm(in) | 38 (1.5”) |

| Max. cutting height (inches) | mm(in) | 600 (23.62”) |

| Max. cutting width | mm(in) | 620 (24.44”) |

| Worktable tilting | 0° ÷ 45° | |

| Min./max. blade dimensions | mm(in) | 8/35 (0.31” x 1.37”) |

| Standard three-phase motor | mm(in) | 6,7kW (9hp) |

| Exhaust outlet diameter | mm(in) | No. 2 x 120 (4.75”) |

| Miter gauge slot | 3/8 x 3/4 | |

MINIMUM INSTALLATION REQUIREMENTS | ||

| Extraction air consumption | m3/h | 1630 |

| Exhaust air speed (dry shavings) | m/s | 20 (0.81”) |

| Installed motor power | VA | 3600 |

| Voltage Frequency | 220 V 60 Hz |

For any questions concerning delivery, please contact eshopsupportus@scmgroup.com

To ensure a clear and hassle-free purchasing experience, below are the weight and dimensions of the packaged machine at the time of delivery:

| Dimensions | ||

| Lenght | in | 23 |

| Width | in | 98 |

| Height | in | 45 |

| Weight | lb | 1031 |

Before completing the purchase, the customer can choose between two delivery options:

1 - Pickup from Our Warehouse (Incoterm EXW - Ex Works)

The machine can be picked up personally from our warehouses. Prior to purchase, verify in which locations this unit is available.

2 - Delivery by Dedicated Freight Carrier (Incoterm DAP - Delivered at Place)

By selecting this option, SCM will entrust the delivery to a specialized freight carrier, ensuring secure transport managed by professionals. The service includes:

- Advance phone notice before delivery

Important: Due to the size of the machine, unloading from the truck is the customer’s responsibility. A forklift or appropriate equipment will be required to safely complete the unloading process. Internal transport and positioning inside the premises are not included.

If the machine is purchased with the installation service, after the order is completed, SCM Service or an authorized center will contact the customer to coordinate: the installation date, the necessary equipment, he required documentation for installation.

SCM Group US is not responsible for any damages, injuries, or losses resulting from improper installation, unsafe or incorrect use of the machine, failure to follow the manufacturer’s guidelines, or any modifications made by the customer or third parties.

Customers who choose to opt out of professional installation assume full responsibility for ensuring that the machine is installed and operated in strict accordance with the provided instructions and safety standards. If you have not received the user manual, please contact us with the machine’s serial number to obtain it before installation and use.

SCM Group US disclaims all liability for any accidents, malfunctions, or consequential damages resulting from non-compliance with these guidelines.

Installation & Warranty Activation

If installation is not included in your purchase and you would like to have the machine installed by our technicians, please contact us.

If SCM installation is not required, you must complete and submit the warranty activation form (VICA) within 10 business days from the machine’s delivery date. The form will be provided with the purchase order confirmation or can be requested by contacting us. Failure to submit the form on time may result in the warranty being voided.

For any further information or assistance, please feel free to contact us.