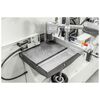

balestrini pico tn CNC tenoning machine

(Steuern, Versand und Installation sind im Preis nicht enthalten.)

balestrini pico tn is the numerical control tenoning machine with double worktable, dedicated to the execution of square or round-end tenons with 0°-90° tilting for the production of chairs, tables and furnishing accessories.

The productivity is ensured by the two cast iron worktables that allow pendulum machining at the work-piece end in a continuous cycle.

Simplified programming with Maestro active joint software that enables the selection of numerous macros for the programming of tenons with any angle.

*Photos may include optional equipment. Please verify availability and compatibility under Product Details and Specs.

N.2 front tilting worktables equipped with adjustable reference fence, workpiece clamping cylinder and rear reference stop for maximum versatility. Easily create tenons on angles or compound angles.

The 10” touch screen PC Panel with Maestro active joint programming software guarantees ease-of-use. Tenon macros simplify programming.

Capable of producing a different tenon on each table increasing flexibility.

Easily produce a wide variety of tenon styles in different materials.

Tenon cycles have been refined to produce a high-quality finish even on difficult profiles.

The tenoning unit with 4.5 kW electro-spindle and 9,000-12,000 rpm rotation speed allows tenon cycles with maximum productivity, up to 720 tenons per hour.

- Additional pair of reference stops and reference stop on each worktable for processing workpieces shorter than 350

- N.1 tenoning cutter with hogger for machining solid wood or plastics

- Tenon depth easily adjusted

- Perfect for production of outdoor furniture

- Tool-holder shank with 25 mm diameter

- Movement of interpolated axes by Brushless motors for high accuracy and rapidity

*Does not include power cable

TECHNICAL FEATURES |

|

|

Worktable |

| |

Dimensions of each table | mm (in) | 315 x 360 (12.4 x 14.1) |

Longitudinal tilt | 0° ÷ 20° | |

Work-piece support fence rotation | 0° ÷ 45° | |

Work-piece cross-section (width x thickness) |

| |

With straight cut min. | mm (in) | 15 x 15 (0.59 x 0.59) |

With straight cut max. | mm (in) | 200 x 50 (7.87 x 1.96) |

Work-piece length |

| |

Min. | mm (in) | 120 + length of tenon (4.74) |

Max. | mm (in) | 880 + length of tenon (34.64) |

Tenon dimensions |

| |

Max. horizontal tenon length | mm (in) | 200 (7.87) |

Max. thickness | mm (in) | 30 (1.18) |

Height | mm (in) | 8 ÷ 50 (0.31 x 1.96) |

Tenon |

| |

Tilting | 0° ÷ 90° | |

Productivity |

| |

Max. | tenons/h | 720 |

Minimum installation requirement |

| |

Installed power | 10 KVA - 15 A | |

Air consumption system machine | NL/min (CFM) | 250 (9.0) |

Suction air consumption, n. 1 Ø 100 mm | m3/h (CFM) | 1 x 850 (500) |

Suction air consumption, n. 2 Ø 150 mm | m3/h (CFM) | 2 x 1900 (1,120) |

Suction air speed | m/s (ft/sec) | 25/30 (90) |

USA version / Voltage - Frequency | 400EU – 50/60 Hz |

For any questions concerning delivery, please contact eshopsupportus@scmgroup.com

To ensure a clear and hassle-free purchasing experience, below are the weight and dimensions of the packaged machine at the time of delivery:

| Dimensions | ||

| Lenght | in | 125 |

| Width | in | 56 |

| Height | in | 82 |

| Weight | lb | 2710 |

Before completing the purchase, the customer can choose between two delivery options:

1 - Pickup from Our Warehouse (Incoterm EXW - Ex Works)

The machine can be picked up personally from our warehouses. Prior to purchase, verify in which locations this unit is available.

2 - Delivery by Dedicated Freight Carrier (Incoterm DAP - Delivered at Place)

By selecting this option, SCM will entrust the delivery to a specialized freight carrier, ensuring secure transport managed by professionals. The service includes:

- Advance phone notice before delivery

Important: Due to the size of the machine, unloading from the truck is the customer’s responsibility. A forklift or appropriate equipment will be required to safely complete the unloading process. Internal transport and positioning inside the premises are not included.

If the machine is purchased with the installation service, after the order is completed, SCM Service or an authorized center will contact the customer to coordinate: the installation date, the necessary equipment, he required documentation for installation.

SCM Group US is not responsible for any damages, injuries, or losses resulting from improper installation, unsafe or incorrect use of the machine, failure to follow the manufacturer’s guidelines, or any modifications made by the customer or third parties.

Customers who choose to opt out of professional installation assume full responsibility for ensuring that the machine is installed and operated in strict accordance with the provided instructions and safety standards. If you have not received the user manual, please contact us with the machine’s serial number to obtain it before installation and use.

SCM Group US disclaims all liability for any accidents, malfunctions, or consequential damages resulting from non-compliance with these guidelines.

Installation & Warranty Activation

If installation is not included in your purchase and you would like to have the machine installed by our technicians, please contact us.

If SCM installation is not required, you must complete and submit the warranty activation form (VICA) within 10 business days from the machine’s delivery date. The form will be provided with the purchase order confirmation or can be requested by contacting us. Failure to submit the form on time may result in the warranty being voided.

For any further information or assistance, please feel free to contact us.