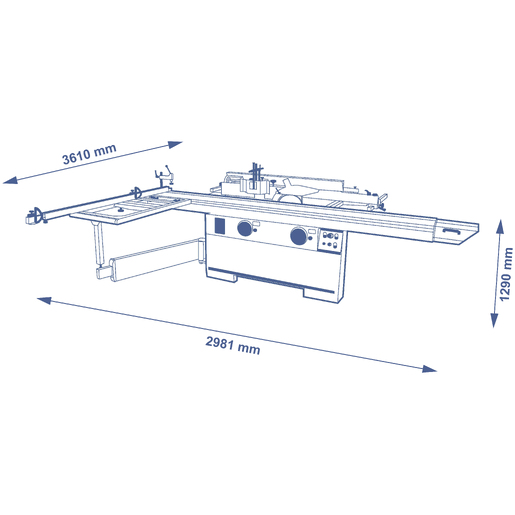

minimax cu 410e Universal combined machine

(Steuern, Versand und Installation sind im Preis nicht enthalten.)

The first distinctive feature of the cu 410e universal combination machine is the ease of use guaranteed by the system of surfacing worktable opening toward the inside of the machine. This combination machine is also equipped with anodized-extruded guides with support and rapid locking and an effective feeding system for the planer. These features make this machine easy-to-use for any type of machining. Another amazing feature of this machine is its maximum flexibility when using the cutters, with the spindle moulder unit equipped with various speeds. The machine is equipped with a spindle moulder hood with micrometric adjustment, very useful for moulding work.

*Photos may include optional equipment. Please verify availability and compatibility under Product Details and Specs.

Incredible cutting thanks to the saw unit with a blade (not included) that has a maximum diameter of 315 mm with the scoring blade installed

Optimal support also to larger pieces, with the sliding table 360 mm wide. The guides are secured with a procedure of aluminum riveting, so that to ensure an exceptional precision and smoothness

The planer infeed roller has a helicoidal profile to guarantee firm and constant work piece feed, while the outfeed roller, in sandblasted steel, maintains the perfect post-processing finishing

SCM Thundercut App for mobile devices: optimizer/sequencer even for not skilled workers

Maximum stability and rigidity in all working conditions, thanks to a large spindle moulder column made entirely of cast iron

- The saw unit closed loop structure is made of a heavy cast iron and is supported firmly under the table by two lateral supports in a crescent shape: these solutions give strength and rigidity, guaranteeing perfect cutting results

- The scoring blade is adjustable from the outside without tools and allows fast and accurate positioning with no play

- The sliding table ensures a top quality precision with a smooth and silent action, a self-cleaning dustproof system, and a long lasting accuracy with no adjustments required

- The sliding table is provided with an additional table for the support of panels with large dimensions

- Panel loading is easy on the large squaring frame with an idle roller at the end. The telescopic squaring fence has two reversible stops so to have precise references on both sides of it

- The angular cutting device with flip-over stops allows to rapidly perform mitre cuts without moving the squaring fence and it is very useful for small work pieces

- The “Tersa” cutter block, without fixing screws, makes the 4 knives substitution extremely fast. Moreover, the automatic knives clamping by means of the centrifugal force ensures safe and precise machining

- For an impeccable finishing, the pressure of the thicknesser feed rollers can be adjusted according to the type of wood machined

- For the saw and the surfacing planer the machine has professional fences designed to be easy to remove and to allow a rapid changeover from one type of operation to another

- The 4 standard speeds of the shaper are ideal for any type of machining, from shaping to routing

- The shaper has a tiltable spindle moulder 90° ÷ 45° for the maximum versatility and has an handwheel on the front of the machine, with numerical readout, for easy unit positioning

- The shaper spindle is surrounded by a cast iron “cup” to protect the internal mechanical components from shavings and sawdust

- The spindle moulder fence has reference pins for easy re-positioning and numeric readouts for micrometric adjustments

- The flip over support for the feeder (not included) is very fast, practical and comfortable when this one is not in use and has to be moved out from the working area

- With the cast iron mortiser complete with self-centering (Wescott type) chuck drilling holes and mortises are easily carried out

*Does not include power cable

MACHINE CONFIGURATION

(Options and accessories included with this machine)

- Version with maximum squaring stroke 2600 mm

- Belt driven scoring unit complete with blade

- "DADO SET" capability

- Angular cutting device with flip-over stops

- Additional table on the sliding table

- Round sliding bars on parallel fence and on surface fence

- Cast iron mortiser

- 0-16 mm self-centering (Wescott type) chuck

- "Tersa" cutterblock Ø 85 mm with 4 knives with rapid locking system

- Spindle moulder fence with 3 controlled adjustments max. tool Ø 240 mm

- Tiltable spindle moulder 90° ÷ 45°

- Electric pre-setting (CE and USA-Canada versions) and flip over support for feeder

- Reverse spindle rotation (non CE)

- Wheels for machine movement

- Numerical readouts for the units positioning

- 3 single-phase motors 3,6kW (4,8hp) 60Hz

- Interchangeable spindle

- Spindle moulder shaft of 1 1/4""

- Locking by countersunk socket screw

| TECHNICAL FEATURES | ||

| Planer: | ||

| Useful working width | mm(in) | 300 (11.81”) |

| Cutter block diameter | mm(in) | 72 (2.81”) |

| Maximum stock removal | mm(in) | 4 (0.19”) |

| Surfacing tables total length | mm(in) | 1510 (59.44”) |

| Thicknessing table dimensions | mm(in) | 585 x 300 (23” x 11.81)” |

| Feed speed on thicknesser | 7 (0.25”) | |

| Minimum ÷ maximum working height on thicknesser | mm(in) | 3 ÷ 230 (0.12”÷9”) |

| Circular saw: | ||

| Cast iron saw-spindle moulder worktable dimensions | mm(in) | 1115 x 335 (43.87”x13.19”) |

| Blades tilting | 90° ÷ 45° | |

| Maximum saw blade diam. with scoring blade installed | mm(in) | 315 (12.37”) |

| Maximum saw blade projection from table at 90°/45° | mm(in) | 100/78 (3.94”/3.06”) |

| Maximum squaring stroke | mm(in) | 1600 (62.94”) |

| Cutting width on parallel fence | mm(in) | 820 (32.31”) |

| Spindle moulder: | ||

| Spindle diameter | mm(in) | 1 1/4" |

| Max. useful spindle length | mm(in) | 100 (3.94”) |

| Spindle moulder speed | rpm | 4200/8400/12.000 |

| Max. tool diameter when profiling | mm(in) | 210 (8.25”) |

| Max. diam. of tool lowered under the table at 90° | mm(in) | 180 (7.06”) |

| Other technical features: | ||

| Single-phase motors | 3,6kW (4,8hp) 60Hz | |

| Exhaust outlets diameter | mm(in) | 120 (4.75”) |

| MINIMUM INSTALLATION REQUIREMENTS | ||

| Section of electrical cable | mm2(in) | 6 (0.25”) |

| Power absorption | A | 20 |

| Voltage - frequency | 230V - 60Hz |

For any questions concerning delivery, please contact eshopsupportus@scmgroup.com

To ensure a clear and hassle-free purchasing experience, below are the weight and dimensions of the packaged machine at the time of delivery:

| Dimensions | ||

| Lenght | in | 116 |

| Width | in | 64 |

| Height | in | 46 |

| Weight | lb | 2461 |

Before completing the purchase, the customer can choose between two delivery options:

1 - Pickup from Our Warehouse (Incoterm EXW - Ex Works)

The machine can be picked up personally from our warehouses. Prior to purchase, verify in which locations this unit is available.

2 - Delivery by Dedicated Freight Carrier (Incoterm DAP - Delivered at Place)

By selecting this option, SCM will entrust the delivery to a specialized freight carrier, ensuring secure transport managed by professionals. The service includes:

- Advance phone notice before delivery

Important: Due to the size of the machine, unloading from the truck is the customer’s responsibility. A forklift or appropriate equipment will be required to safely complete the unloading process. Internal transport and positioning inside the premises are not included.

If the machine is purchased with the installation service, after the order is completed, SCM Service or an authorized center will contact the customer to coordinate: the installation date, the necessary equipment, he required documentation for installation.

SCM Group US is not responsible for any damages, injuries, or losses resulting from improper installation, unsafe or incorrect use of the machine, failure to follow the manufacturer’s guidelines, or any modifications made by the customer or third parties.

Customers who choose to opt out of professional installation assume full responsibility for ensuring that the machine is installed and operated in strict accordance with the provided instructions and safety standards. If you have not received the user manual, please contact us with the machine’s serial number to obtain it before installation and use.

SCM Group US disclaims all liability for any accidents, malfunctions, or consequential damages resulting from non-compliance with these guidelines.

Installation & Warranty Activation

If installation is not included in your purchase and you would like to have the machine installed by our technicians, please contact us.

If SCM installation is not required, you must complete and submit the warranty activation form (VICA) within 10 business days from the machine’s delivery date. The form will be provided with the purchase order confirmation or can be requested by contacting us. Failure to submit the form on time may result in the warranty being voided.

For any further information or assistance, please feel free to contact us.