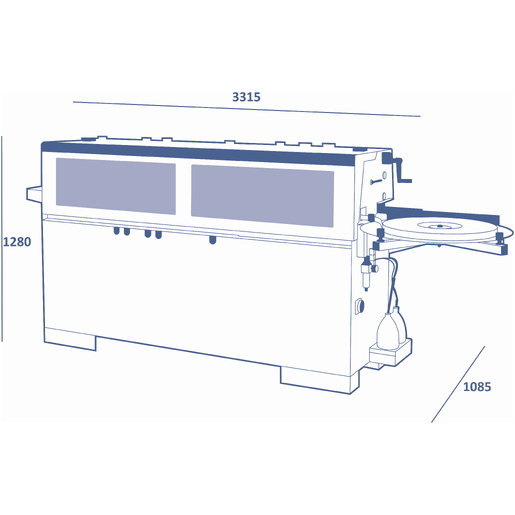

me 35tr Automatic edge bander with pre-milling unit and end-cutting/rounding combined unit

(Price does not include taxes, shipping and installation)

The SCM me 35tr automatic edge bander offers the “very best” performance in edge banders at this level.

The panel edge surface is without any imperfections before the gluing operation thanks to the pre-milling unit. It utilizes 2 diamond tools with opposing rotation and timed intervention that, through the removal operation, corrects any panel imperfections caused by the saw cutting process and panel storage. This edge bander has other technologically advanced solutions such as the end-cutting/rounding combined unit that carries out the end-cutting and the rounding of thin and thick edges up to 3 mm, for the best panel finish quality.

*Photos may include optional equipment. Please verify availability and compatibility under Product Details and Specs.

High productivity by the track feed speed. The encoder for feeding panel control ensures the total working cycle control

Technologically advanced solutions such as the end-cutting/rounding combined unit that carries out the end-cutting and the rounding of thin and thick edges up to 3 mm, for the best panel finish quality.

A new innovative system of self-lubrication of the glue pot, enables a more extensive use of the edge banding machine without the necessity of lubrication. Two rollers press the edge banding evenly and efficiently on to the panel edge for an ideal edge application

Panel edge surface without any imperfections before the gluing operation thanks to the pre-milling unit. It utilizes 2 diamond tools with opposing rotation and timed intervention that, through the removal operation, corrects any panel imperfections caused by the saw cutting process and panel storage.

The simple and intuitive PLC control system allows an easy selection of all the main functions and guides the operator during maintenance, cleaning and diagnostic operations.

- Pre-milling unit with independent exhaust system that ensures the panel cleaning removing dust and chips

- The glue inside the gluing unit is heated rapidly and evenly by the resistances.

- The gluing unit automatic reduces the glue temperature after a temporary halt in production when using the machine, avoiding burning of the glue.

- The glue spreading roller with electrical resistance inside provides a uniform glue spread and always at the maximum working temperature even on panels at the maximum working height.

- The kit for glue pot rapid substitution highly increases the machine productivity, reducing downtimes for replacement operations.

- The end-cutting/rounding combined unit is equipped with a tool and a high frequency motor to provide the best finishing quality of the machined edge. Furthermore, the absence of belts or other driving systems prevents any vibration assuring the best results at all times.

- To obtain excellent quality finishing the trimming unit has rotating copiers to align perfectly to the work piece and high frequency motors which generate high cutter rotating speed, reducing to a minimum any marks left from trimming and guaranteeing the absence of vibrations

- For the maximum machine versatility, the cutters are designed for straight or radius trimming of any type of edge, whether it is thick or thin, made of PVC, ABS, melamine, laminate or wood

- The edge thickness to machine with the trimming unit is easily set by means of two numerical readouts.

- The edge scraping unit grants high finishing quality of plastic material edges thanks to the radius knives that ensure the complete elimination of any marks left from the trimming unit tools.

- The edge scraping unit has a user-friendly device for exclusion of the unit when it is not in use

- The glue scraping unit eliminates any excess glue on the panel/edge joint for an optimal cleaning. The rotating copying device allows to machine even the most delicate panels.

- The brushing unit with tilted, vertically adjustable motors optimizes the cleaning/polishing action on the panel edge.

- The high efficiency LED lamp for the machine interior improves the view of the operating units inside the machine without needing to open the cabin allowing a safe observation of the machine during the processing.

*Does not include power cable

MACHINE CONFIGURATION

(Options and accessories included with this machine)

- Edge scraping unit

- Brushing unit

- Glue scraping unit

- Internal machine lightening

- Tools kit radius 3 mm (instead of standard radius 2 mm)

| TECHNICAL FEATURES | |||

| Workable dimensions | [mm] | 3000 x 525 (118.12” x 20.69”) | |

| Workable height | [mm] | 904 (35.56”) | |

| Thickness of rolled edges | [mm] | 0.4 ÷ 3 (up to 0.12”) | |

| Min. ÷ max. panel height | [mm] | 8 ÷ 50 (0.31 ÷ 1.94”) | |

| Min. panel length/width with rolled edges | [mm] | 120/110 (4.75” / 4.31”) | |

| Feed speed | [m/min] | 7 (23 f/min) | |

| Feed motor power | [kW] | 0.55 | |

| Pneumatic operating pressure | [bar] | 6.5 | |

| Exhaust outlet diameter (glue pot) | [mm] | 60 (2.37”) | |

| No. 2 exhaust outlets diameter (trimming unit) | [mm] | 60 (2.37”) | |

| No. 2 exhaust outlets diameter (pre-milling unit) | [mm] | 80 (3.12”) | |

No 1 exhaust hood (end cutting unit-rounding unit) diameter | [mm] | 60 (2.37”) | |

| Operating temperature | [°C] | 20 ÷ 190 (68 ÷ 374 °F) | |

| PRE-MILLING UNIT | |||

| Motor power | [kW] | 3 | |

| Tools rotation speed | [rpm] | 7.200 | |

| No. 2 diamond tools | Ø 80 mm H=56 Z2 (3.12”) | ||

| Stock removal | [mm] | 0,5/1/1,5/2 (up to 0.06”) | |

| GLUE POT UNIT | |||

| Motor power | [kW] | 0.25 | |

| Glue capacity | [kg] | ~ 0.8 (1.8 lbs) | |

| COMBINED END CUTTING-ROUNDING UNIT | |||

| Motor power | [kW] | 0.35 | |

| Tool | Ø 58 mm Z4 (4.94”) | ||

| Tool rotation speed | [rpm] | 12.000 | |

| TRIMMING UNIT | |||

| Upper/lower motor power | [kW] | 2 x 0.35 | |

| Widia cutters | Ø 55.3 mm Z3 (2.19”) | ||

| Cutters rotation speed | [rpm] | 12.000 | |

| Other technical features: | |||

| USA Voltage-Frequency | 230V-60Hz |

For any questions concerning delivery, please contact eshopsupportus@scmgroup.com

To ensure a clear and hassle-free purchasing experience, below are the weight and dimensions of the packaged machine at the time of delivery:

| Dimensions | ||

| Lenght | in | 101 |

| Width | in | 35 |

| Height | in | 62 |

| Weight | lb | 1500 |

Before completing the purchase, the customer can choose between two delivery options:

1 - Pickup from Our Warehouse (Incoterm EXW - Ex Works)

The machine can be picked up personally from our warehouses. Prior to purchase, verify in which locations this unit is available.

2 - Delivery by Dedicated Freight Carrier (Incoterm DAP - Delivered at Place)

By selecting this option, SCM will entrust the delivery to a specialized freight carrier, ensuring secure transport managed by professionals. The service includes:

- Advance phone notice before delivery

Important: Due to the size of the machine, unloading from the truck is the customer’s responsibility. A forklift or appropriate equipment will be required to safely complete the unloading process. Internal transport and positioning inside the premises are not included.

If the machine is purchased with the installation service, after the order is completed, SCM Service or an authorized center will contact the customer to coordinate: the installation date, the necessary equipment, he required documentation for installation.

SCM Group US is not responsible for any damages, injuries, or losses resulting from improper installation, unsafe or incorrect use of the machine, failure to follow the manufacturer’s guidelines, or any modifications made by the customer or third parties.

Customers who choose to opt out of professional installation assume full responsibility for ensuring that the machine is installed and operated in strict accordance with the provided instructions and safety standards. If you have not received the user manual, please contact us with the machine’s serial number to obtain it before installation and use.

SCM Group US disclaims all liability for any accidents, malfunctions, or consequential damages resulting from non-compliance with these guidelines.

Installation & Warranty Activation

If installation is not included in your purchase and you would like to have the machine installed by our technicians, please contact us.

If SCM installation is not required, you must complete and submit the warranty activation form (VICA) within 10 business days from the machine’s delivery date. The form will be provided with the purchase order confirmation or can be requested by contacting us. Failure to submit the form on time may result in the warranty being voided.

For any further information or assistance, please feel free to contact us.