nova s 520 Thicknessing planer - Xylent

(Price does not include taxes, shipping and installation)

The nova s 520 thicknessing planer has several features, one of the most important is the worktable stability, ensured by 4 screws with a large diameter combined with the 2 side linear guides. Another great feature is the rollers interchangeability. Perfect finishing obtained by quick and easy changeover of the rollers that allows the operator to configure the machine drive function in case of special requirements, such as a minimum removal of fine wood and/or batches where multiple pieces of different thicknesses are processed.

*Photos may include optional equipment. Please verify availability and compatibility under Product Details and Specs.

The stopping of the work piece and the presence of notches on its surface are eliminated due to the movement system on connecting rods of all the three feeding rollers that allows their vertical displacement by rotation so to have the best linear feeding.

The 4 dust protected screws with a large diameter combined with the 2 side linear guides ensure worktable sturdiness and stability, eliminating the necessity of locking it in position and guaranteeing high precision and reliability over time.

Quick and easy changeover of the rollers thanks to their interchangeable system that allows the operator to configure the machine drive function in case of special requirements such as minimum removals of fine woods.

The “Xylent” spiralknives cutter block gives an exceptional finish with reduced noise during machining thus to provide a more comfortable working environment

STANDARD EQUIPMENT

- Monoblock Base and Cast iron table

The solid, welded base undergoes a treatment call normalization which stabilizes the metal and assures exact tolerances. All machine mechanisms are mounted, aligned, and referenced to the base. This design is vastly superior to frames that are bolted together and have no true reference point.

The cast iron tables are machine polished. These castings are ribbed to ensure maximum strength and to avoid problems with the tables warping or breaking

during use. - Powered planer table lifting; 2 speeds with micrometric adjustment

- Numerical readout of working height with decimal control

- Planer table movements by means of 4 steel screws, with 2 side linear guides

- Helicoidal steel infeed roller

- Rubber-coated steel outfeed roller

- Interchangeable feed rollers

TOOLING INCLUDED

- Qty. 84 xylent knifes 15x15x2.5 mm (0.56x0.56x0.12”)

- Push stick and push handle

- Toolbox: Wrenches, allen wrenches, user manual, spare parts catalog

SAFETY/PROTECTIONS

- Soundproof infeed and outfeed barriers

- Overload switch protection

- Auxiliary low voltage circuit (110 volt)

- Emergency pushbutton

- Main power switch can be locked in the off position with a padlock

MACHINE CONFIGURATION

- 10.06.74 USA version

- R1.00.86 nova s 520

- 93.07.34 Volt 220

- 93.15.01 Frequency 60 hz

- 57.03.23 "Xylent" spiralknife cutterblock with 3 series of knife complete with:

- 84 plates 15x15x2.5mm with 4 selflocking and selfcentering screw knives

- 1 dynamometric key for the correct and safe use of the locking

- 2 inserts for the dynamometric key

- 57.03.28 10 spare inserts kit (15x15x2.5) for Xylent spindle

- 57.01.38 Worktable with 2 idle rollers

- 08.06.36 Seaworthy packing

- 10.99.91 Machine language: ENGLISH

*Does not include power cable

TECHNICAL SPECIFICATIONS | |

Motor power | 11 HP - 8 kW |

Working width | 520 mm (20.44”) |

Worktable length | 900 mm (35.37”) |

Maximum depth of cut | 8 mm (0.31”) |

Cutterblock diameter | 120 mm (4.75”) |

Cutterhead speed | 4500 rpm |

No. of knives | No. 84 // 15x15x2.5 mm (0.56x0.56x0.12”) |

Min/max. working thickness | 3.5 / 300 mm (0.12 / 11.75”) |

Minimum working length / width | 220 / 10 mm (8.69 / 0.37”) |

Feed speed | 5-8-12-18 m/min (16-26-39-59 ft/min) |

Exhaust outlets diameter | 150 mm (5.87”) |

Installation requirements | |

Nominal extraction air consumption | 1300 m3/h (754 CFM) |

Air exhaust speed | 20 m/s (66 ft/s) |

Electrical requirements **subject to change; must be verified prior to installation** | 220 V – 60 Hz – 3 phase – 25A |

For any questions concerning delivery, please contact eshopsupportus@scmgroup.com

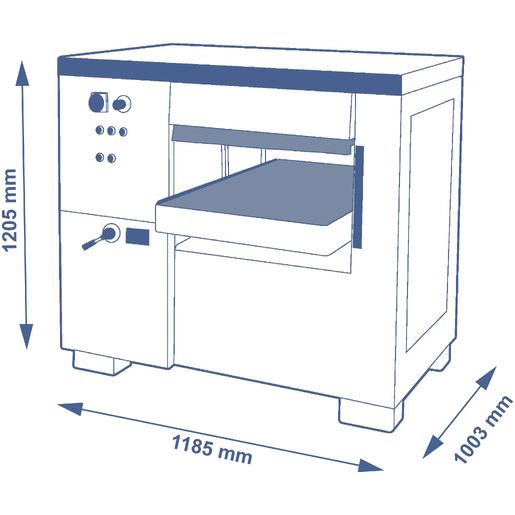

To ensure a clear and hassle-free purchasing experience, below are the weight and dimensions of the packaged machine at the time of delivery:

| Dimensions | ||

| Lenght | in | 56 |

| Width | in | 43 |

| Height | in | 55 |

| Weight | lb | 1736 |

Before completing the purchase, the customer can choose between two delivery options:

1 - Pickup from Our Warehouse (Incoterm EXW - Ex Works)

The machine can be picked up directly from our warehouses. Prior to purchase, verify in which locations this unit is available.

2 - Delivery by Dedicated Freight Carrier (Incoterm DAP - Delivered at Place)

By selecting this option, SCM will entrust the delivery to a specialized freight carrier, ensuring secure transport managed by professionals. The service includes:

- Advance phone notice before delivery

- Hydraulic tail lift for unloading the machine from the truck

Important: Deliveries are made exclusively to the curbside, meaning the machine will be dropped off at the entrance of the building or designated location. Internal transport and positioning inside the premises are not included. If a forklift or other equipment is needed for internal movement, the customer is responsible for arranging these operations.

If the machine is purchased with the installation service, after the order is completed, SCM Service or an authorized center will contact the customer to coordinate: the installation date, the necessary equipment, he required documentation for installation.

SCM Group US is not responsible for any damages, injuries, or losses resulting from improper installation, unsafe or incorrect use of the machine, failure to follow the manufacturer’s guidelines, or any modifications made by the customer or third parties.

Customers who choose to opt out of professional installation assume full responsibility for ensuring that the machine is installed and operated in strict accordance with the provided instructions and safety standards. If you have not received the user manual, please contact us with the machine’s serial number to obtain it before installation and use.

SCM Group US disclaims all liability for any accidents, malfunctions, or consequential damages resulting from non-compliance with these guidelines.

Installation & Warranty Activation

If installation is not included in your purchase and you would like to have the machine installed by our technicians, please contact us.

If SCM installation is not required, you must complete and submit the warranty activation form (VICA) within 10 business days from the machine’s delivery date. The form will be provided with the purchase order confirmation or can be requested by contacting us. Failure to submit the form on time may result in the warranty being voided.

For any further information or assistance, please feel free to contact us.