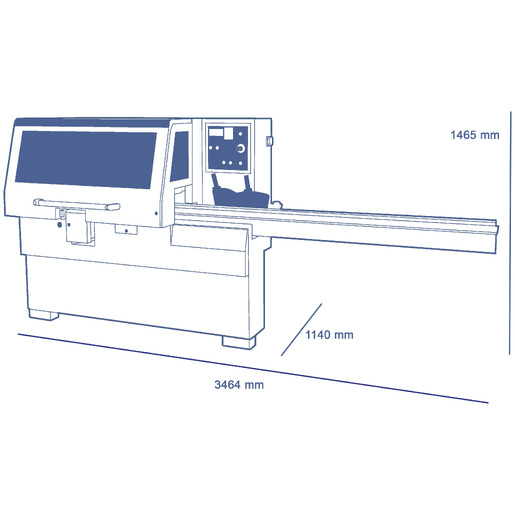

Profiset 40ep Automatic planer and throughfeed moulder

Starting from {0}

(Price does not include taxes, shipping and installation)

The profiset 40ep is a 4 spindles automatic planer and throughfeed moulder

with 10mm profiling capacity on the vertical spindles.

It is characterized by a sturdy structure and the maximum versatility and safety that guarantees in all machining.

The Ready electronic control ensures a simple and intuitive machine programming and set up for the best use also by not-skilled operators.

The profiset 40ep machines solid wood, MDF type panels or other similar materials lengthways and guarantees the highest possible value of the machined piece thanks to the SCM high quality standards, so that represents a very important technology for both artisan and industrial woodworking.

*Photos may include optional equipment. Please verify availability and compatibility under Product Details and Specs.

Programming becomes simple and effective with the “READY” electronic control

• Automatic positioning control of left vertical spindle and

top horizontal spindle

• Feed speed programming

• Mode: manual, semi-automatic and

automatic with memory capacity up to 99

programs

• Additional functions: calculator and hour counter.

The use of the reference engraver on the lower spindle ensures the optimal reference guide of the workpiece to be machined.

Therefore a perfect straightening is guaranteed.

Profiset 40ep is always ready to use, thanks to the automatic control of the working sections.

The feed speed is equipped with only one push button for the sequential motors start.

- Pressers placed in front and behind the top horizontal spindle are simultaneously adjustable for a rapid setup system

- Vertical pressers for large workpieces are placed in front of left vertical spindle to be effective in any situation

- Powered feeding group before surface planer, equipped with 2 rollers, with lever for exclusion of the same

- The infeed table and the infeed right guide have a transversal adjustment by means of a parallelogram system which ensures an absolute precision

- All adjustments of working units are controlled from the machine front with mechanical decimal readout of work section.

- The idle roller placed on the outfeed table, typical feature of industrial level machines, guarantees a very effective feeding and the best finishing

- Kit of 4 planer cutterheads and reference engraver for heavy-duty machining including reference engraver, 2 planer cutterheads for horizontal spindles, 2 planer cutterheads for vertical spindles

- The manual pump for the worktable lubrication positioned in the operator area facilitates its use, assuring always the best smooth movement of the workpiece

- The 2300 mm infeed worktable allows to machine very long workpiece

- Automatic motors start in sequence

MACHINE CONFIGURATION

(Options and accessories included with this machine)

- Powered feeding group before surfacer planer with lever for exclusion of the same

- Vertical pressers for large workpieces placed in front of left vertical spindle

- 2300 mm infeed table

- Kit of 4 planer cutterheads and reference engraver for heavy-duty machining

| Technical features | Profiset 40 EP |

| Min. working width (finished section) | 23mm |

| Max. working width (finished section) | 180mm |

| Min. working height (finished section) | 10mm |

| Max. working height (finished section) | 105mm |

| Min. length of single workpiece | 300mm |

| Feed speed | 6 - 12 m/min |

| Feed motor power | 0,7/1,1 kW (1/1,5 Hp) |

| Horizontal spindles motor power (single) | 7,5 kW (10 Hp) |

| Vertical spindles motor power (single) | 7,5 kW (10 Hp) |

| Spindle speed | 6.000 rpm |

| Spindles diameter | 35mm |

| Vertical spindles length | 120mm |

| Horizontal spindles length | 190mm |

| Min/max cutterheads diam. on horizontal spindles | 100mm |

| Min/max cutterheads diam. on vertical spindles | 100 - 120mm |

| Profiling capacity without axial stroke on vertical spindles | 10mm |

| Groups adjustment with respect to the diameter of cuttersheads | +/- 1mm |

| Feed rollers diameter | 120mm |

| Infeed worktable length | 2.300mm |

| Fast adjustment of infeed table and fence | 10mm |

| Manual pump for table lubrication | STD |

| Exhaust outlets diameter | no. 4 120mm |

INSTALLATION REQUIREMENTS

Suction air consumption m³/h 4880

Suction air speed m/sec 30

power absorption [A] 75

voltage - frequency 220V - 60Hz

For any questions concerning delivery, please contact eshopsupportus@scmgroup.com

To ensure a clear and hassle-free purchasing experience, below are the weight and dimensions of the packaged machine at the time of delivery:

| Dimensions | ||

| Lenght | in | 130 |

| Width | in | 45 |

| Height | in | 73 |

| Weight | lb | 2280 |

Before completing the purchase, the customer can choose between two delivery options:

1 - Pickup from Our Warehouse (Incoterm EXW - Ex Works)

The machine can be picked up personally from our warehouses. Prior to purchase, verify in which locations this unit is available.

2 - Delivery by Dedicated Freight Carrier (Incoterm DAP - Delivered at Place)

By selecting this option, SCM will entrust the delivery to a specialized freight carrier, ensuring secure transport managed by professionals. The service includes:

- Advance phone notice before delivery

Important: Due to the size of the machine, unloading from the truck is the customer’s responsibility. A forklift or appropriate equipment will be required to safely complete the unloading process. Internal transport and positioning inside the premises are not included.

If the machine is purchased with the installation service, after the order is completed, SCM Service or an authorized center will contact the customer to coordinate: the installation date, the necessary equipment, he required documentation for installation.

SCM Group US is not responsible for any damages, injuries, or losses resulting from improper installation, unsafe or incorrect use of the machine, failure to follow the manufacturer’s guidelines, or any modifications made by the customer or third parties.

Customers who choose to opt out of professional installation assume full responsibility for ensuring that the machine is installed and operated in strict accordance with the provided instructions and safety standards. If you have not received the user manual, please contact us with the machine’s serial number to obtain it before installation and use.

SCM Group US disclaims all liability for any accidents, malfunctions, or consequential damages resulting from non-compliance with these guidelines.

Installation & Warranty Activation

If installation is not included in your purchase and you would like to have the machine installed by our technicians, please contact us.

If SCM installation is not required, you must complete and submit the warranty activation form (VICA) within 10 business days from the machine’s delivery date. The form will be provided with the purchase order confirmation or can be requested by contacting us. Failure to submit the form on time may result in the warranty being voided.

For any further information or assistance, please feel free to contact us.