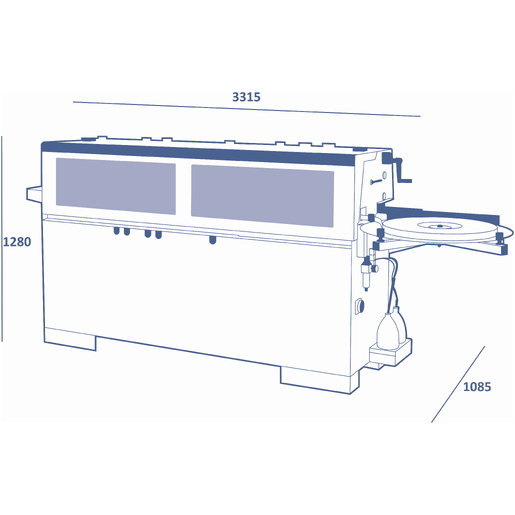

me 35tr Automatic edge bander with pre-milling unit and end-cutting/rounding combined unit - 3 ph

$31,475.00

(Price does not include taxes, shipping and installation)

The SCM me 35tr automatic edge bander offers the “very best” performance in edge banders at this level.

The panel edge surface is without any imperfections before the gluing operation thanks to the pre-milling unit. It utilizes 2 diamond tools with opposing rotation and timed intervention that, through the removal operation, corrects any panel imperfections caused by the saw cutting process and panel storage. This edge bander has other technologically advanced solutions such as the end-cutting/rounding combined unit that carries out the end-cutting and the rounding of thin and thick edges up to 3 mm, for the best panel finish quality.

*Photos may include optional equipment. Please verify availability and compatibility under Product Details and Specs.

Incoming 1

Item currently in production

High productivity by the track feed speed. The encoder for feeding panel control ensures the total working cycle control

Technologically advanced solutions such as the end-cutting/rounding combined unit that carries out the end-cutting and the rounding of thin and thick edges up to 3 mm, for the best panel finish quality.

A new innovative system of self-lubrication of the glue pot, enables a more extensive use of the edge banding machine without the necessity of lubrication. Two rollers press the edge banding evenly and efficiently on to the panel edge for an ideal edge application

Panel edge surface without any imperfections before the gluing operation thanks to the pre-milling unit. It utilizes 2 diamond tools with opposing rotation and timed intervention that, through the removal operation, corrects any panel imperfections caused by the saw cutting process and panel storage.

The simple and intuitive PLC control system allows an easy selection of all the main functions and guides the operator during maintenance, cleaning and diagnostic operations.

STANDARD EQUIPMENT

- Eye-S 10” touch screen control on machine infeed side

- Maestro active edge interface

- Immediate and intuitive panel programming thanks to the adaptive 3D design of the processing with real time preview

- No possibility of error with the machining guidance system that suggests the correct machine set up to the operator

- machine frame made of high rigidity ribbed steel to guarantee an excellent support for the operating units

- Kit for glue pot rapid substitution which includes the rapid locking/unlocking device and the double thermoregulation system to manage two different working temperatures (ex. for the poliurethane glues use)

- top thick steel pressure beam with rubber coated wheels

- panel support roller which can be extended on the entire length of the machine

- numeric indicator of the selected panel thickness

- manual adjustment of top beam with automatic positioning of the operating units according to the selected panel thickness

TOOLING INCLUDED

- 2 pre mill diamond cutters

- 2 mm radius tooling set

- Toolbox: Wrenches, allen wrenches, user manual, spare parts catalog

SAFETY/PROTECTIONS

- safety enclosure

- Main power switch can be locked in the off position with a padlock

- Emergency pushbutton located on the control panel

MACHINE CONFIGURATION

Options and accessories included in this quotation

- 10.99.99 USA safety regulations version

- 93.07.51 220 volt

- 93.12.15 Frequency 60 hz

- 08.69.81 Pallet

- 10.99.91 Machine language: ENGLISH

- R0.07.44 Me 35tr - Usa/Canada version

- PRE-MILLING UNIT

Complete with 2 diamond tools, 80 mm diameter.

It allows a very good panel finish and linearity during pre-machining. It is equipped with independent exhaust hoods and a air blower which cleans the panel from dust and chips.

It is possible to carry vertical adjustments of the tools to use them even in the final sharpening phase - GLUE POT UNIT, EDGE LOADING AND PRESSING SYSTEM

- hot melt glue with quick heat up system and internally teflon coated to allow an easy glue replacement

- glue application on the panel by means of glue spreading roller

- temperature adjustment of the applied glue integrated in the PLC control

- device for automatic recovery of unused glue

- automatic edge loading system for rolled edges with shear device for 3 mm max. thickness edges

- coil holder plate, 730 mm diameter

- pressing unit with n. 2 edge steel rollers with counterposed conicity

- adjustable infeed fence with numeric readout

- automatic lowering of the glue pot temperature after a temporary non-use of the machine

- self-lubrification system of the glue pot

- COMBINED END CUTTING-ROUNDING UNIT

- end cutting of front and rear exceeding edge

- Full rounding and corner rounding*

*Based on machine configuration - see tooling included

Note: not suitable for strips of solid wood or High Pressure Laminate (e.g. Formica, Nevamar, Wilsonart)

- TOP and BOTTOM TRIMMING UNIT

- high frequency motors

- front rotating copiers with chrome plated surfaces and vertical copying discs for an accurate positioning of tools with reference to the cutting point

The unit is provided with 55.3 mm diameter combined cutters: - the radius, part of the cutter, is used to trim radius edges (1-2-3 mm*) and chamfered thin edges

- the straight part of the cutter is used for the trimming of edges in wood up to 5 mm.

Changing from radius edge to edge in wood is done easily by moving the cutters

The edge thickness is displayed on 2 numeric readouts.

*Based on machine configuration – see tooling included

- 58.06.53 EDGE SCRAPING UNIT

It assures an excellent vibration free finish thanks to its high rigidity structure.

High working precision thanks to the horizontal and vertical copying discs, which assure an accurate positioning of the knives in relation to the cutting point.

It allows the finishing of 1-2-3 mm* PVC/ABS edges

Pair of knives included.- numerical readout for the positioning

- Manual exclusion of the unit

*Based on machine configuration – see tooling included

- 58.04.44 BRUSHING UNIT

Tilted, vertically adjustable motors to optimize the cleaning and polishing of the edge.

*Does not include power cable

TECHNICAL SPECIFICATIONS

Worktable dimensions | 3000 x 525 mm (118.06” x 20.62”) |

Worktable height | 904 mm (35.56”) |

Thickness of rolled edges | 0.4 - 3 mm (0.02 – 0.06”) |

Thickness of edges in strips **not compatible with END CUTTING-ROUNDING UNIT** | Up to 5 mm (0.19”)

|

Min. ÷ max. panel height | 8 - 50 mm (0.31 – 1.94”) |

Min. panel length/width with rolled edges | 120 / 110 mm (4.75 – 4.31”) |

Feed speed | 7 m/min ( 23 ft/min) |

Feed motor power | 0.65 Kw |

Operating temperature | 20 – 190 °C (68 – 374 °F) |

PREMILLING UNIT | |

Motor | 3 Kw - 7200 rpm |

Diamond cutter | 2 x Ø 80 mm H=56 Z2 |

Stock removal | 0.5 – 1 – 1.5 – 2 mm (0 – 0.08”) |

GLUE POT UNIT | |

Motor | 0.3 Kw |

Glue capacity | ~0.8 kg (2 lbs) |

COMBINED END CUTTING-ROUNDING UNIT **not compatible with edges in strip or HPL** | |

Motor | 0.2 Kw - 12000 rpm |

Blade | Ø 125 mm Z 12 |

TOP and BOTTOM TRIMMING UNIT | |

Motor | 0.35 Kw - 12000 rpm |

Cutters | Ø 58 mm Z4 |

BRUSHING UNIT | |

Motor power | 2 x 0.17 Kw - 2.800 rpm |

Exhaust outlets diameter: no. 2 pre-milling unit outlet no. 1 glue pot outlet no. 1 end cutting/rounding unit outlet no. 2 trimming unit outlets no. 1 grooving unit outlet (*unit not included*) |

80 mm (3.12”) 60 mm (2.31”) 60 mm (2.31”) 60 mm (2.31”) 60 mm (2.31”) |

Installation requirements | |

Nominal extraction air consumption | 1536 m3/h (890 CFM) |

Air exhaust speed | 20 m/s (66 ft/s) |

Pneumatic operating pressure | 6.5 bar |

Electrical requirements ***subject to change; must be verified prior to installation*** | 220 V – 60 Hz – 3phase – ~30 A

|

For any questions concerning delivery, please contact eshopsupportus@scmgroup.com

To ensure a clear and hassle-free purchasing experience, below are the weight and dimensions of the packaged machine at the time of delivery:

| Dimensions | ||

| Lenght | in | 101 |

| Width | in | 35 |

| Height | in | 62 |

| Weight | lb | 1500 |

Before completing the purchase, the customer can choose between two delivery options:

1 - Pickup from Our Warehouse (Incoterm EXW - Ex Works)

The machine can be picked up personally from our warehouses. Prior to purchase, verify in which locations this unit is available.

2 - Delivery by Dedicated Freight Carrier (Incoterm DAP - Delivered at Place)

By selecting this option, SCM will entrust the delivery to a specialized freight carrier, ensuring secure transport managed by professionals. The service includes:

- Advance phone notice before delivery

Important: Due to the size of the machine, unloading from the truck is the customer’s responsibility. A forklift or appropriate equipment will be required to safely complete the unloading process. Internal transport and positioning inside the premises are not included.

If the machine is purchased with the installation service, after the order is completed, SCM Service or an authorized center will contact the customer to coordinate: the installation date, the necessary equipment, he required documentation for installation.

SCM Group US is not responsible for any damages, injuries, or losses resulting from improper installation, unsafe or incorrect use of the machine, failure to follow the manufacturer’s guidelines, or any modifications made by the customer or third parties.

Customers who choose to opt out of professional installation assume full responsibility for ensuring that the machine is installed and operated in strict accordance with the provided instructions and safety standards. If you have not received the user manual, please contact us with the machine’s serial number to obtain it before installation and use.

SCM Group US disclaims all liability for any accidents, malfunctions, or consequential damages resulting from non-compliance with these guidelines.

Installation & Warranty Activation

If installation is not included in your purchase and you would like to have the machine installed by our technicians, please contact us.

If SCM installation is not required, you must complete and submit the warranty activation form (VICA) within 10 business days from the machine’s delivery date. The form will be provided with the purchase order confirmation or can be requested by contacting us. Failure to submit the form on time may result in the warranty being voided.

For any further information or assistance, please feel free to contact us.