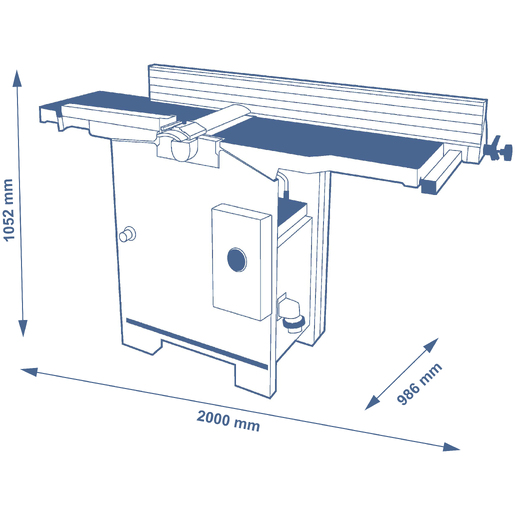

minimax fs 41c Surfacing-thicknessing planer - Xylent

(Price does not include taxes, shipping and installation)

The surfacing-thicknessing planer powerful and user friendly, for D.I.Y. woodworkers and craftsmen workshops.

This 16” Jointer/Planer combo machine offers power and precision in a compact size for any shop. With long jointer tables, and sturdy fence, this machine is a quality product, made in Italy, for a value price. Find out why this machine may be perfect for you.

*Photos may include optional equipment. Please verify availability and compatibility under Product Details and Specs.

For an impeccable finish, the pressure of the thicknesser feed rollers can be adjusted according to the type of wood machined.

The very long surfacing fence is made of extruded aluminium and ensures an absolute rigidity.

The “Xylent” spiralknives cutter block gives an exceptional finish with reduced noise during machining thus to provide a more comfortable working environment.

- The “Xylent” cutter block also improves the dust extraction due to the production of very small chips

- Each cutter of the “Xylent” block has 4 tips which can be rotated into the cutting position when worn, therefore increasing the knives production life before they require replacement

- The thicknesser infeed roller has helical toothing to guarantee strong, constant work piece feed

- The sandblasted steel thicknesser outfeed roller maintains the perfect post-machining finish.

- Handwheel with gravitational numerical readout for an easy and precise positioning of the thicknessing table

*Does not include power cable

MACHINE CONFIGURATION

(Options and accessories included with this machine)

- Wheels for machine movement

- "Xylent" spiralknife cutterblock with 3 series of knives

- 10 spare inserts kit (15x15x2,5) for Xylent spindle

- Handwheel with gravitational numerical readout for the thicknessing table positioning

- Single-phase motor 3,6kW (4,8hp) 60Hz

| TECHNICAL FEATURES | ||

| Working width | mm(in) | 410 (16.12”) |

| Max. stock removal | mm(in) | 4 (0.19”) |

| Surfacing tables total length | mm(in) | 1800 (70.87”) |

| Thicknessing table dimensions | mm(in) | 410 x 605 (16.12” x 23.81”) |

| Feed speed on thicknesser | m(ft)/min | 7 (0.25”) |

| Min. ÷ max.working height on thicknesser | mm(in) | 3 ÷ 230 (0.12” ÷ 9”) |

| Other technical features: | ||

| Single-phase motor | 3,6kW (4,8hp) 60Hz | |

| Exhaust hoods diameter | mm(in) | 120 (4.75”) |

| MINIMUM INSTALLATION REQUIREMENTS | ||

| Section of electrical cable | mm2(in2) | 6(0.25'') |

| Power absorption | A | 20 |

| Voltage - frequency | 230V - 60Hz |

For any questions concerning delivery, please contact eshopsupportus@scmgroup.com

To ensure a clear and hassle-free purchasing experience, below are the weight and dimensions of the packaged machine at the time of delivery:

| Dimensions | ||

| Lenght | in | 83 |

| Width | in | 35 |

| Height | in | 46 |

| Weight | lb | 797 |

Before completing the purchase, the customer can choose between two delivery options:

1 - Pickup from Our Warehouse (Incoterm EXW - Ex Works)

The machine can be picked up personally from our warehouses. Prior to purchase, verify in which locations this unit is available.

2 - Delivery by Dedicated Freight Carrier (Incoterm DAP - Delivered at Place)

By selecting this option, SCM will entrust the delivery to a specialized freight carrier, ensuring secure transport managed by professionals. The service includes:

- Advance phone notice before delivery

Important: Due to the size of the machine, unloading from the truck is the customer’s responsibility. A forklift or appropriate equipment will be required to safely complete the unloading process. Internal transport and positioning inside the premises are not included.

If the machine is purchased with the installation service, after the order is completed, SCM Service or an authorized center will contact the customer to coordinate: the installation date, the necessary equipment, he required documentation for installation.

SCM Group US is not responsible for any damages, injuries, or losses resulting from improper installation, unsafe or incorrect use of the machine, failure to follow the manufacturer’s guidelines, or any modifications made by the customer or third parties.

Customers who choose to opt out of professional installation assume full responsibility for ensuring that the machine is installed and operated in strict accordance with the provided instructions and safety standards. If you have not received the user manual, please contact us with the machine’s serial number to obtain it before installation and use.

SCM Group US disclaims all liability for any accidents, malfunctions, or consequential damages resulting from non-compliance with these guidelines.

Installation & Warranty Activation

If installation is not included in your purchase and you would like to have the machine installed by our technicians, please contact us.

If SCM installation is not required, you must complete and submit the warranty activation form (VICA) within 10 business days from the machine’s delivery date. The form will be provided with the purchase order confirmation or can be requested by contacting us. Failure to submit the form on time may result in the warranty being voided.

For any further information or assistance, please feel free to contact us.