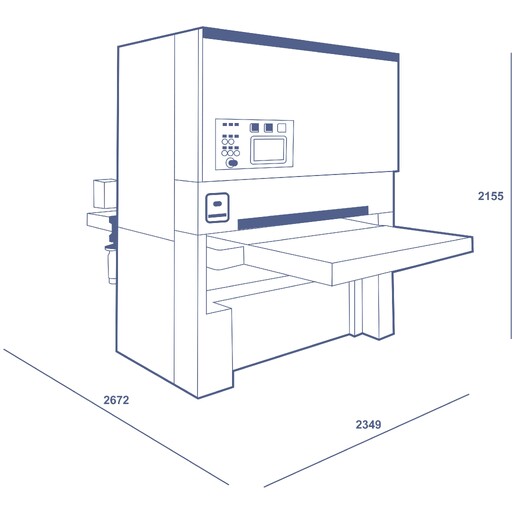

dmc sd 60 Automatic wide belt sander (RCS 135 version)

A$75,351.00

(Price does not include taxes, shipping and installation)

EX Demo Sydney Technology Centre Machine

dmc sd 60 is an extremely versatile, reliable and user-friendly automatic wide belt sander which allows the sanding of solid wood, the pre-sanding and sanding of veneered panels and the finishing of painted surfaces.

*This machine requires mandatory installation. Installation will be quoted after purchase. For any further information or assistance, please feel free to contact us.

**Photos may include optional equipment. Please verify availability and compatibility under Product Details and Specs.

Diamond-shaped belt

it provides the best work piece traction, and the increased support area also ensures maximum stability.

“Mesar” sectional pad

Higher quality results due to the special shape of the sectors that allows the operator to intervene “softly” but also in an “aggressive” way, simply by varying the working pressure. The setting of the pad position and the possibility of using foils of different thickness increases its versatility.

“LOGIC SC” ELECTRONIC PROGRAMMER: easily avoid mistakes.

Simple and intuitive, allowing the operator to set all processing parameters in sequence and then launch them with the touch of a button. The possibility to store various work programs to retrieve the machine settings most commonly used makes it ideal even for unskilled operators.

- R140/45 - 45Sh rubber-coated sanding roller, 140mm diameter, in 1st position + oscillating blower

- R160/30 - 30Sh rubber-coated sanding roller, 160mm diameter, in 2nd position + oscillating blower

- Infeed and outfeed roller conveyors for long workpieces support;

- Belt feed with 0,75 kW (1 hp) mechanical speed variator with adjustable feed belt speed from 3,5 to 18 m/min

- “Logic SC” electronic programmer

- Led indicator for panel introduction. Simple and intuitive, communicating to the operator where and when the panel has to be introduced into the machine and optimising the standard wear of the sanding belt; this ensures a better quality finish and reduced machine costs.

- Electronic readout of working thickness;

- On/off pneumatic selector on the roller unit for the roller position adjustment according to the abrasive belt width;

- On/off pneumatic selector for pad unit and combined unit. It allows the roller exclusion, or the sanding pad exclusion or both of them, from the sanding process while maintaining the working table position unchanged;

- “Mesar” sectional pad: the best finish. Higher quality results due to the special shape of the sectors that allows the operator to intervene “softly” but also in an “aggressive” way, simply by varying the working pressure;

- Inverter with 11 kW (15hp) main motor for the adjustment and the electronic readout from control panel of the sanding belt speed from 3 to 18 m/sec

- Electronic positioning device for a precise and fast working table opening.

- Oscillating belt cleaning blower on the 1st / 2nd group: Electronically controlled timing and only when the workpiece is in the machine, it guarantees reliability over time and reduces

compressed air consumption to a minimum. Particularly advisable when machining painted work pieces.

MACHINE CONFIGURATION

(Options and accessories included with this machine)

- "B" version for RCS

- Grooved rubber coated pressure roller - 2nd position

- Grooved rubber coated pressure roller - 3rd position

- Infeed and outfeed support rollers for long workpieces

- Oscillating belt cleaning blower on the 1st group

- Oscillating belt cleaning blower on the 2nd group

- Inverter with 0,75 kW (1 hp) motor

- "LOGIC SC" electronic control

- R45" 45SH rubber-coated sanding roller - 1st group

- CR30 30 SH rubber-coated sanding roller - 2nd group

- Inverter with 11 kW (15hp) main motor

TECHNICAL FEATURES | ||

Working width | mm | 1350 |

Min/max machining thickness | mm | 4-170 |

Sanding belt width | mm | 1370 |

Abrasive belts length | mm | 2150 |

Standard main motor power | kW (hp) | 11 (15) |

Feed belt motor power | Kw (hp) | 0.75 (1) |

Feed belt speed | m/min | 3.5/18 with inverter |

MINIMUM INSTALLATION REQUIREMENT | ||

Compressed air consumption | [Nl/min] / [Ft3/min] | 1594 |

Extraction air consumption | [Nl/min] / [Ft3/min] | 4730 |

Exhaust air speed | [m/sec] | 22 |

Installed motor power | [kVA] | 24 |

C.E. Version - Voltage/Frequency | [V] - [Hz] | 400-50 |