e 20 manual edge bander for straight and shaped panels

C$15,685.00

(Taxes not included)

The e 20 is the manual edge bander designed to be economic, reliable and practical; a complete machine for the edge banding of straight and shaped panels. Equipped with a glue pot, it can edge band PVC, ABS, wood laminate etc. and not pre-glued edges.

Ideal solution for small and medium series jobs.

Increased productivity and ease of use with the new 4,3” touch-screen

easy adjustment of height, edge thickness and panel.

Edge feeding and motorized pressure roller with electronic speed adjustment, to create an edge banding at the most suitable speed.

Electronic temperature adjustment and precise glue dosage control.

Glue tank and sliding base of the edge coated in Teflon for simple cleaning and quick maintenance.

*Photos may include optional equipment. Please verify availability and compatibility under Product Details and Specs.

** Adjustable tilting table and Infeed fence not included. Can be purchased separately. For details contact us at Add Support Ticket | SCM Shop Canada (scmgroup.com)

4,3” touch screen with advanced functions complete with:

* Adjustment of the edge feed speed from 3 to 8 m/min

* Management of manual work modes, programmed cutting and measure of the panel perimeter

* Automatic calculation of the required edge length with reference to the most common geometries

Teflon-coated hot melt glue pot installed underneath the worktable to ensure a continuous glue recirculation and avoid its overheating. Powerful heating system for an immediate use with timed stand-by

- High rigidity and stability steel monoblock base

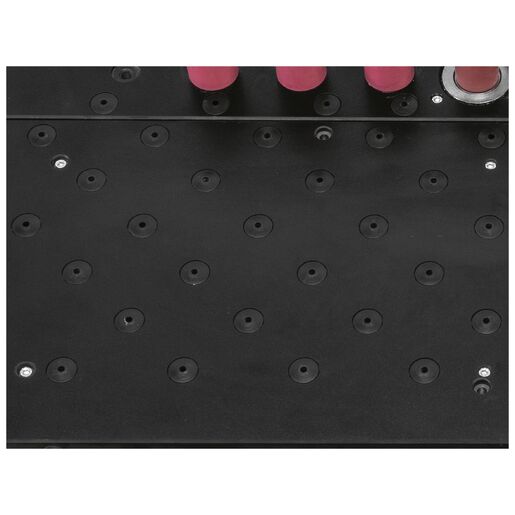

- Anti-scratch phenolic multilayer work table with modular holes complete with supports for the panels support to guarantee no risk of damaging the moving panels

- Front extension for the support of large dimensions panels

- Shear device for rolled edges complete with 780 mm (30.69”) coil-holder plate

- Glue application of edging material by means of a powered glue spreading roller

- 3-roller outfeed fence for a better gluing quality on large dimensioned straight

- Wheels for an easy machine movement

- Emergency pushbutton located on the front machine side, padlockable main switch, Stabilised power supply for auxiliary circuit 24V in direct current.

- Tilting worktable adjustable from 0 to 45° which allows the simple edge banding of panels with sides not in square with reference to the support table and guarantees an absolute precision.

*Does not include power cable

** Adjustable tilting table and Infeed fence not included. Can be purchased separately. For details contact us at Add Support Ticket | SCM Shop Canada (scmgroup.com)

MACHINE CONFIGURATION

(Options and accessories included with this machine)

- 780 mm coil-holder plate

- 3-roller outfeed fence

- Front extension for the support of large dimensions panels

- Wheels to allow machine movement

- Tilting worktable adjustable from 0 to 45°

| TECHNICAL FEATURES | ||

| Thickness of pre-cut edges in strips | mm (in) | 0,4 – 3(0.19” - 0.12”) |

| Thickness of edges with shear device: | ||

| (80 mm height) | mm (in) | 0,4 – 1,5 (1/64” – 1/16”) |

| (50 mm height) | mm (in) | 0,4 - 2,5 (1/64” – 3/32”) |

| (45 mm height) | mm (in) | 0,4 – 3 (1/64” – 1/8”) |

| Edges height | mm (in) | 10 – 84 (0.39” – 3.31”) |

| Panels thickness | mm (in) | 8 – 80 (0.31” - 3.12”) |

| Minimum panel width | mm (in) | 50 (1.94”) |

| Minimum panel length to be applied | mm (in) | 290 (11 13/32”) |

| Minimum internal radius with 0,4 mm edge thickness (concave profile) | mm (in) | 25 (0.94”) |

| Minimum external radius with 0,4 mm edge thickness (convex profile) | mm (in) | 5 (0.19”) |

| Feed speeds | m/min (ft/min) | 3-4-5-6-7-8 (10-13-16-20-23-26) |

| MINIMUM INSTALLATION REQUIREMENTS | ||

| Average compressed air consumption | l/min | 10 (0.37”) |

| Installed motor power | kW | 6,9 |

| Operating temperature | °C (°F) | 140 -220 ( 284 -428) |

| Canada Version – Voltage /Frequency | 220V / 60Hz |

For any questions concerning delivery, please contact eshopsupportca@scmgroup.com

To ensure a clear and hassle-free purchasing experience, below are the weight and dimensions of the packaged machine at the time of delivery:

| Dimensions | ||

| Lenght | cm (in) | 105 (42) |

| Width | cm (in) | 114 (45) |

| Height | cm (in) | 110 (44 ) |

| Weight | kg (lb) | 270 (596) |

Before completing the purchase, the customer will choose the following delivery option:

Dedicated Courier Delivery (Incoterm DAP - Delivered at Place)

By selecting this option, SCM will entrust delivery to a specialized carrier, ensuring safe transportation handled by professionals. The service includes:

- Advance phone notice before delivery

- Hydraulic tail lift for unloading the machine from the truck

Important: Deliveries are made exclusively to the curbside, meaning the machine will be dropped off at the entrance of the building or designated location. Internal transport and positioning inside the premises are not included. If a forklift or other equipment is needed for internal movement, the customer is responsible for arranging these operations.

If the machine is purchased with installation service, after the order is completed, SCM Service or an authorized center will contact the customer to coordinate: the date of installation, equipment needed, and documentation required for installation.

SCM Group Canada is not responsible for any damages, injuries, or losses resulting from improper installation, unsafe or incorrect use of the machine, failure to follow the manufacturer’s guidelines, or any modifications made by the customer or third parties.

Customers who choose to opt out of professional installation assume full responsibility for ensuring that the machine is installed and operated in strict accordance with the provided instructions and safety standards. If you have not received the user manual, please contact servicecanada@scmgroup.com with the machine’s serial number to obtain it before installation and use.

SCM Group Canada disclaims all liability for any accidents, malfunctions, or consequential damages resulting from non-compliance with these guidelines.

Installation & Warranty Activation

If installation is not included in your purchase and you would like to have the machine installed by our technicians, please contact servicecanada@scmgroup.com or call 437-335-6781 (Monday to Friday, 7:30 AM – 4:30 PM EST) for assistance.

If SCM installation is not required, you must complete and submit the warranty activation form (VICA) to servicecanada@scmgroup.com within 10 business days from the machine’s delivery date. The form will be provided with the purchase order confirmation or can be requested by contacting us. Failure to submit the form on time may result in the warranty being voided.