L'invincibile ti 7 Shaper with tilting spindle

$64,975.00

(Price does not include taxes, shipping and installation)

Buying "L'invincibile ti 7" spindle moulder means you get a customised solution because it is the result of years of experience, technical research, Italian creativity.

The heart of this machine is the Electrospindle: machining centre technology service for the woodworker. Absolute machining precision and absence of vibration due to the perfectly balanced structure of the electrospindle. The electrospindle’s direct drive eliminates maintenance procedures common with conventional belt driven systems. But this spindle moulder has many great features: discover them all by going through the product page.

*Photos may include optional equipment. Please verify availability and compatibility under Product Details and Specs.

Item currently not available

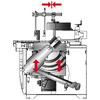

Electrospindle: machining centre technology service for the woodworker.

Absolute machining precision and absence of vibration due to the perfectly balanced structure of the electrospindle. The electrospindle’s direct drive eliminates maintenance procedures common with conventional belt driven systems

Less movement for faster setting-up, due to the unique movement mechanism of the spindle (SCM patent), which allows the operator to position independently the height of the tool with the tilted spindle and the moulder fence.

Tool detection system: setting up speedily and safely. The system eliminates any manual operation for setting up the required work allowing the operator to automatically input all the work data. Higher operator’s safety: the possibility to select only the programs associated with the tool installed eliminates possible dangerous situations. Less input data, fewer errors, immediately ready to work

Rapid tool changeover HSK: flexible and safe with a time saving of 75% in the machine set up compared to the traditional systems. Maximum coupling precision with the double air jet system that keeps contact surfaces clean.

EASY TOUCH: the satisfaction of fast and easy-to-use control of all machine functions with the 12” flat touch-screen colour display. The system guides the operator every step of the way offering suggestions that avoids the operator making any mistakes. Information windows instruct the operator as to what to do on the next operation ensuring the operator works in complete safety

STANDARD EQUIPMENT

- Upper mobile control panel "eye-S”

- 15” touch-screen display

- Control of the 6 working axes with manual, semi-automatic and automatic modes

- storage capacity up 1000 programs with relevant picture

- storage capacity up 1000 tools with relevant picture

- USB port

- pre-set for network connection

- tool peripheral speed management

- operator's help for the more recurrent machining

- Automatic tool detecting system

complete with mobile electromagnetic readout to identify the tool installed on the machine.

With reference to the detected tool, the control can provide:- saved programs associated to the detected tool

- detected tool speed

- strokes of every axis to avoid eventual collisions

- coordinates for the detected tool and define an origin (new zero point for the machine) on three different points of the tool profile chosen by the operator

- "Flex" fence with automatic adjustment managed by electronic control

Move the entire fence with reference to the tool diameter.

Adjust the infeed fence in reference to the requested removal.

The FLEX system allows to exclude of the fence from worktable.

Includes aluminum profiling fence with connecting bars.

- Electric presetting for feeder support (400V)

- Reverse spindle rotation

- "FAST" section table with automatic adjustment managed from control

- Automatic star-delta start

- H-E version with:

- 10 HP (7.5kW) electrospindle

- HSK 63B rapid tool changer

- inverter for electronic programming of the shaft rotating speed from 900 to 12000 rpm

- 1 tool-holder shaft with HSK B 63 taper, complete with electronic device (transponder) for the tool detection system

- air blower system to maintain cleaned coupling contact surface

- SCM Exclusive system for the electrospindle movement

- vertical shaft movement on two linear precision guides through preloaded recirculating ball bearing pads

- tilting from -45.50° to +45.50° with "dove-tail" arch-formed cast-iron fence

- movement through recirculating ball screw (SCM patent pending)

TOOLING INCLUDED

- 1 HSK 63B 1 ¼” spindle

- Toolbox: Wrenches, allen wrenches, user manual, spare parts catalog

SAFETY/PROTECTIONS

- Spindle protection for operations

- Electronic brake ensuring stop, even in case of voltage drop

- Safety sensors for changing tool operation, rotating stop control, tool taper locking/unlocking control

- Safety microswitch on motor acess door

- Emergency pushbuttons

- Main power switch can be locked in the off position with a padlock

- Overload switch protection

- 24V auxiliary low voltage circuit

- "CSA" rated electrical components

MACHINE CONFIGURATION

- 10.14.28 USA/CAN safety regulations version

- R0.08.44 L'invincibile TI 7 Usa/Canada version

- 93.07.34 220 volt

- 53.02.21 Autotransformer for 220V – 400V

- 93.15.01 Frequency 60 hz

- 13.13.05 Spindle moulder shaft of 1 1/4"

- 08.97.05 Seaworthy packing

- 10.99.91 Machine language: ENGLISH

*Does not include power cable

TECHNICAL SPECIFICATIONS | |

Worktable dimensions | 1200 x 750 mm (47.19” x 29.5”) |

Motor power | 10HP - 7.5 kW |

Spindle tilting | ± 45.50° |

Working length of spindle | 140 mm (5.5”) |

Spindle base projection from table with interch. spindle | 54 mm (2.12”) |

Max tool diam. retractable under worktable | 300 x 75 mm (11.75” x 2.94”) |

Exhaust outlets diameter: spindle hood machine base machine base |

120 mm (4.69”) 150 mm (5.87”) 100 mm (3.94”) |

Installation requirements | |

Nominal extraction air consumption | 2600 m3/h (1500 CFM) |

Air exhaust speed | 20 m/s (66 ft/s) |

Pneumatic operating pressure | 6 bar |

Electrical requirements ***subject to change; must be verified prior to installation*** | 220 V – 60 Hz – 3phase – tbd A

Note: The machine is 400V. This configuration includes an autotrasformer 220V – 400V |

For any questions concerning delivery, please contact eshopsupportus@scmgroup.com

To ensure a clear and hassle-free purchasing experience, below are the weight and dimensions of the packaged machine at the time of delivery:

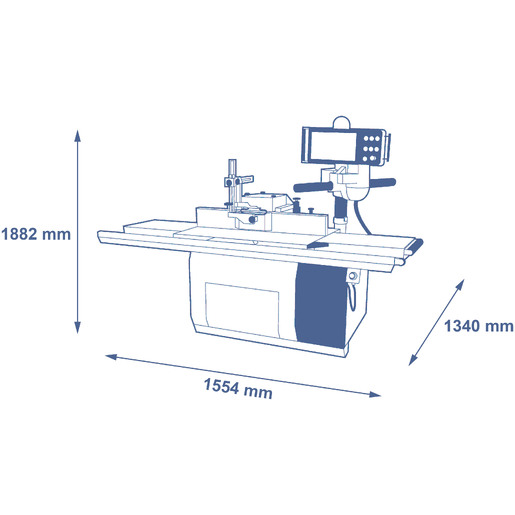

| Dimensions | ||

| Lenght | in | 67 |

| Width | in | 60 |

| Height | in | 86 |

| Weight | lb | 2841 |

Before completing the purchase, the customer can choose between two delivery options:

1 - Pickup from Our Warehouse (Incoterm EXW - Ex Works)

The machine can be picked up directly from our warehouses. Prior to purchase, verify in which locations this unit is available.

2 - Delivery by Dedicated Freight Carrier (Incoterm DAP - Delivered at Place)

By selecting this option, SCM will entrust the delivery to a specialized freight carrier, ensuring secure transport managed by professionals. The service includes:

- Advance phone notice before delivery

- Hydraulic tail lift for unloading the machine from the truck

Important: Deliveries are made exclusively to the curbside, meaning the machine will be dropped off at the entrance of the building or designated location. Internal transport and positioning inside the premises are not included. If a forklift or other equipment is needed for internal movement, the customer is responsible for arranging these operations.

If the machine is purchased with the installation service, after the order is completed, SCM Service or an authorized center will contact the customer to coordinate: the installation date, the necessary equipment, he required documentation for installation.

SCM Group US is not responsible for any damages, injuries, or losses resulting from improper installation, unsafe or incorrect use of the machine, failure to follow the manufacturer’s guidelines, or any modifications made by the customer or third parties.

Customers who choose to opt out of professional installation assume full responsibility for ensuring that the machine is installed and operated in strict accordance with the provided instructions and safety standards. If you have not received the user manual, please contact us with the machine’s serial number to obtain it before installation and use.

SCM Group US disclaims all liability for any accidents, malfunctions, or consequential damages resulting from non-compliance with these guidelines.

Installation & Warranty Activation

If installation is not included in your purchase and you would like to have the machine installed by our technicians, please contact us.

If SCM installation is not required, you must complete and submit the warranty activation form (VICA) within 10 business days from the machine’s delivery date. The form will be provided with the purchase order confirmation or can be requested by contacting us. Failure to submit the form on time may result in the warranty being voided.

For any further information or assistance, please feel free to contact us.