startech cn v Universal NC drilling and grooving machine with F11L drilling head

25% Stock Clearance

$31,481.25(Price does not include taxes, shipping and installation)

startech cn v is the universal NC drilling and grooving machine for both small and medium carpentry dedicated to vertical drilling on the panel surface, horizontal drilling on all four sides and cutting with integrated blade in the "X" direction.

This version is equipped with the high performance F11L drilling head for enhanced machine uptime.

Equipped with patented drilling head with Ro.Ax technology, the ” top” on the market which ensures greater precision, finish quality, drilling feed speed, productivity and drastic reduction in maintenance times (1000 hours non-stop).

Maximum freedom in processing different types of materials (MDF, chipboard, etc) and and also small-sized panels and maximum processing flexibility for "batch 1".

Available 2

Item ready for delivery

Flexible and customized productions combined with speed and precision.

Drilling head F11L positioned above the panel to guarantee accurate machining and thanks to the system that uses the outside of the panel (in sight) as a reference, any differences in thickness are always on the inside of the cabinet (non in sight)

RO.AX technology (Rotoaxial spindle technology), the most efficient spindle on the market with drastic reduction in maintenance times (1000 hours non-stop).

Mobile clamp with floating opening which does not require any adjustment for maximum piece stability

- Base and working table

- Base made of tubular welded steel to create a large support surface, on which the work tables are fixed

- Anti-scratch bakelite work table that does not require any adjustment as the grooved structure allows the head insertion in any working condition and ensures maximum piece stability

- Drilling unit consisting of drilling head with 7 vertical spindles, 4 horizontal spindles and integrated blade

- NC numerical control 10" LCD color display with touch-screen function

- Side supports with rollers that guarantee the best support also of long work pieces.

- Detecting system for calibrating of opposite panel side reference

- Device capable to read the panel dimension along X direction and automatically compensate errors on eventual panel size. This device grants a perfect joint between the panels even if the same are out of tolerance.

- Device to increase the drilling pressure along Z axis; it is particularly useful when machining hard materials or large diameter holes

- Automatic lubrication for an always optimal maintenance of machine efficiency

- Cooling fans inside the electrical cabinet to maintain optimal machine

- performance

- Internal machine lightening which grants an excellent visibility of the workpieces during machining.

|

|

| startech cn v |

| |

| Axes |

|

|

| |

| max. panel dimensions X-Y-Z | mm (inch) | 3000 x 900 x 50 (118.06” x 35.37” x 1.94”) |

| |

| min. panel dimensions X-Y-Z | mm (inch) | 300 x 90 x 10 (11.81” x 3.56” x 0.37”)

|

| |

| max speed X-Y axes | m (feet) / min | 20 (66) |

| |

| Drilling head F11L |

|

|

| |

| Vertical spindles | n. | 7 (4 left and 3 right) |

| |

| Horizontal spindles (along Y axis) | n. | 2 (1+1) |

| |

| Horizontal spindles (along X axis) | n. | 2 (1+1) |

| |

| Fixed integrated blade,(cutting into direction) |

| X |

| |

| max. blade diameter | mm (inch) | 125 (4.87”) |

| |

| max. blade thickness | mm (inch) | 6 (0.19”) |

| |

| motor power | kW | 2,2 |

| |

| spindle speed | rpm | 4200 |

| |

| blade speed | rpm | 5500 |

| |

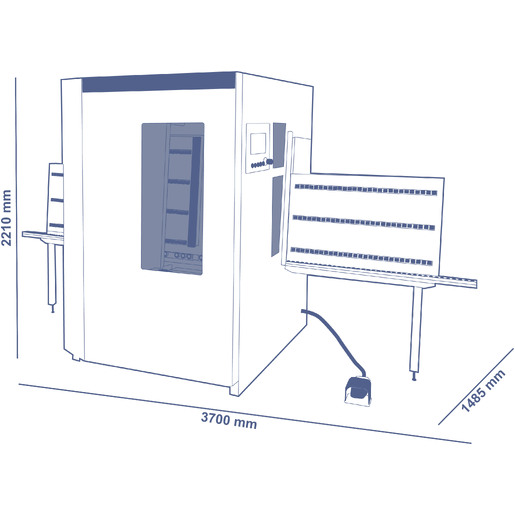

| Minimum installation requirements |

|

| ||

| compressed air consumption | Nl/min | 600 | ||

| extraction air consumption | M³/h (cfm) | 1628 (944) | ||

| exhaust air speed | M (feet) /sec | 20 (66) | ||

| exhaust hood diameter | mm (inch) | 120 (4.75) | ||

| Usa version - Voltage /Frequency |

| 230V – 60HZ | ||

For any questions concerning delivery, please contact eshopsupportus@scmgroup.com

To ensure a clear and hassle-free purchasing experience, below are the weight and dimensions of the packaged machine at the time of delivery:

| Dimensions | ||

| Lenght | in | 82 |

| Width | in | 58 |

| Height | in | 97 |

| Weight | lb | 2146 |

Before completing the purchase, the customer can choose between two delivery options:

1 - Pickup from Our Warehouse (Incoterm EXW - Ex Works)

The machine can be picked up personally from our warehouses. Prior to purchase, verify in which locations this unit is available.

2 - Delivery by Dedicated Freight Carrier (Incoterm DAP - Delivered at Place)

By selecting this option, SCM will entrust the delivery to a specialized freight carrier, ensuring secure transport managed by professionals. The service includes:

- Advance phone notice before delivery

Important: Due to the size of the machine, unloading from the truck is the customer’s responsibility. A forklift or appropriate equipment will be required to safely complete the unloading process. Internal transport and positioning inside the premises are not included.

If the machine is purchased with the installation service, after the order is completed, SCM Service or an authorized center will contact the customer to coordinate: the installation date, the necessary equipment, he required documentation for installation.

SCM Group US is not responsible for any damages, injuries, or losses resulting from improper installation, unsafe or incorrect use of the machine, failure to follow the manufacturer’s guidelines, or any modifications made by the customer or third parties.

Customers who choose to opt out of professional installation assume full responsibility for ensuring that the machine is installed and operated in strict accordance with the provided instructions and safety standards. If you have not received the user manual, please contact us with the machine’s serial number to obtain it before installation and use.

SCM Group US disclaims all liability for any accidents, malfunctions, or consequential damages resulting from non-compliance with these guidelines.

Installation & Warranty Activation

If installation is not included in your purchase and you would like to have the machine installed by our technicians, please contact us.

If SCM installation is not required, you must complete and submit the warranty activation form (VICA) within 10 business days from the machine’s delivery date. The form will be provided with the purchase order confirmation or can be requested by contacting us. Failure to submit the form on time may result in the warranty being voided.

For any further information or assistance, please feel free to contact us.