k 100 evo Automatic single-sided edge bander

10% online discount

10% stock clearance

£22,496.94(Price does not include VAT and delivery)

k 100 evo is the automatic single-sided edge bander for the edge gluing with hot melt glue on straight panels, on the four panel sides, finishing and rounding-off of the panel corners. It is the ideal solution for small artisan companies looking for efficient and superior quality products. Quick set-up of the trimming unit for the machining of 3 different edge types. Great reliability with the high frequency motors.

Optimal managing of the machine thanks to the new 10” touch screen “eye-S” Compact Console with Maestro active edge, operator interface, where all of the machine functions are graphically shown.

Very high edge quality finishing with the trimming unit including rotating copiers. The high frequency motors generate high cutter rotating speed, reducing to a minimum any marks left from trimming and guaranteeing the absence of vibrations.

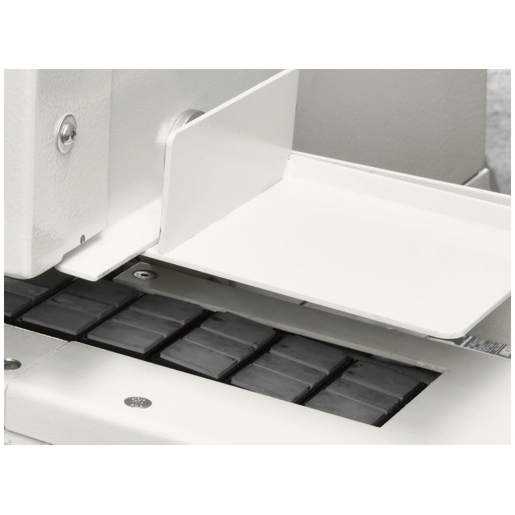

The panel feed speed by track guarantees optimal holding and feeding linearity.

- Top machining units fixed to the presser to allow the automatic positioning according to the panel thickness

· Bottom machining units fixed to the machine base, under the belt, for an accurate panel reference

· Safety enclosure on the entire machine length with polycarbonate windows for the machining unit view during the processing

· Electrical cabinet with door inside the machine base enabling an easy access in case of any maintenance operations

· Panel support rollers positioned parallel to the belt; it can be extended on the entire machine length

· Kit for glue pot rapid replacement that includes the rapid unlocking device and the double thermoregulation system for managing two different working temperatures (i.e. for polyurethane glues use)

· Pre-milling unit with diamond tools; it performs the panel edge obtaining an optimal surface for the glue application and a perfect jointing line with the edge

· Glue pot unit for the automatic gluing with hot melt glue of edges in rolls and strips on straight panels

· Single-motor end cutting unit that carries out the cutting of front and rear exceeding edge

· Trimming unit for the trimming of top and bottom exceeding edge; it includes 2 high frequency motors, rotating copiers, unit manual exclusion and combi cutters (R=2) to machine different edge types.

· Anti-adhesive unit positioned before the pre-milling unit, it prevents the glue sticking to the top and bottom panel surfaces, thus improving the cleaning

· Edge scraping unit fitted with numerical readout for the positioning and with rotating copiers; it eliminates the presence of notches left from the tools on the plastic edges during the trimming

· Glue scraping unit with rotating copier that eliminates any glue excess in the joint between panel and edge, improving the panel cleaning

· Brushing unit with 2 independent motors for the cleaning/polishing of the edge

· Infrared ceramic lamp to heat the panels before the glue application

· Kit for machining edges in strips up to 5 mm for the automatic loading of edges in strips with thickness 0,4-5 mm

· "Nesting" copying device kit for trimming unit and edge scraping unit to perform panels already processed with “nesting” working cycle

MACHINE CONFIGURATION

(Options and accessories included with this machine)

- "AAL" anti-adhesive unit

- "RAS-M" edge scraping unit

- "RC-M" glue scraping unit

- "SP-M" brushing unit

- Infrared ceramic lamp

- Kit for machining edges in strips up to 5 mm

- "Nesting" copying device kit for Trimming unit

- "Nesting" copying device kit for Edge scraping unit

| Technical data | k 100 evo | |

| Track feeding speed | m/min | 7 |

| Panel thickness | mm | 8-50 |

| Thickness of edge in strips | mm | 0,4-3 |

| Thickness of edge in rolls | mm | 0,4-3 |

| Max. section of edge in rolls | mm² | 150 |

| Max. plate diameter | mm | 700 |

| Exceeding material to the panel thickness | mm | 2+2 |

| Distance between two successive panels | mm | 600 |

| Min. panel length with edge in rolls (110 mm min. width) | mm | 160 |

| Min. panel length with edge in strips (110 mm min. width) | mm | 180 |

| Min. length of edge in rolls | mm | 200 |

| Min. length of edge in strips | mm | 220 |

| Min. panel width (210 mm min. length) | mm | 110 |

| Worktable height | mm | 900 |

| Width for fixed panel support roller | mm | 615 |

| Pre-milling unit | ||

| Max. removal | mm² | 55 |

| Thickness removal | mm | 0,5-1-1,5-2 |

| Min. panel width | mm | 110 |

| Motors power S1/S6 | kW | 1,8/2,2 |

| Tool diameter | mm | 80 |

| Tool height | mm | 56 |

| Tool rotating speed | rpm | 8.300 |

| Glue pot unit | ||

| Installed power | kW | 0,25 |

| Glue pot capacity | kg | 0,8 |

| Single-motor end cutting unit | ||

| Motor power | kW | 0,2 |

| Cutters rotating speed | rpm | 12.000 |

| Trimming unit | ||

| Motors power | kW | 0,35 |

| Cutters rotating speed | rpm | 12.000 |

| Min. panel thickness with radius | mm | 12 |

| Vertical/front copiers |

| disc/disc |

| Knives radius | mm | 2 |

| Edge scraping unit | ||

| Min. panel thickness | mm | 12 |

| Vertical/front copiers |

| disc/disc |

| Knives radius | mm | 2 |

| Brushing unit | ||

| Motors power | kW | 0,14 |

| Cutters rotating speed | rpm | 2.800 |

| MINIMUM INSTALLATION REQUIREMENTS |

|

|

| Compressed air consumption L=3300 panel | Nl/cycle | 470 |

| Extracted air consumption | m³/h | 1333 |

| Air speed for suction | m/sec | 20 |

| Current rating | A | 23 |

| CE version – Voltage /Frequency |

| 400V / 50Hz 3 Phases + Neutral + Floor |