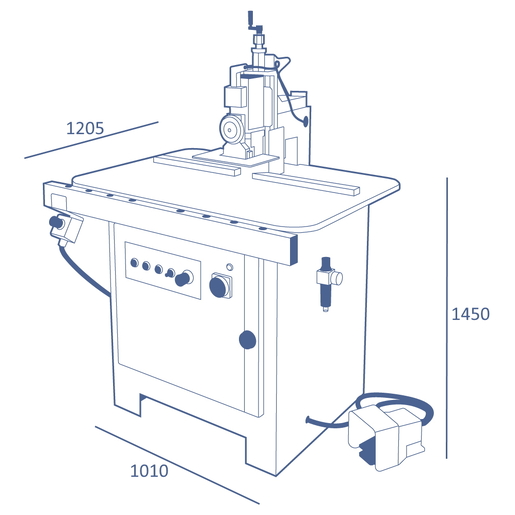

t 20 Manual trimming machine for straight and shaped panels

C$13,200.00

(Taxes not included)

The intelligent and versatile scm t 20 trimming machine that allows you to trim and end cut any type of panel. Designed with exclusive solutions, it allows a quick set up without comparison

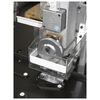

The trimming adjustment is carried out in few seconds and without errors by means of the Scm exclusive device which provides a pivoting ring with a decimal dial. In addition, this allows the adjustment of the vertical copier without using any tool.

Interchangeable copying devices for a rapid and precise set up during machining changeover, eliminating the horizontal adjustment. Possibility to work panels with tilted edge up to 45°. Inverter for the best finishing on any type of edge

*Photos may include optional equipment. Please verify availability and compatibility under Product Details and Specs.

Item currently not available

Possibility to work panel with tilted edge

Copying devices with vertical -scratch copiers kit to ensure the optimal machine operation and front interchangeable rotating copying devices kit with hardened, ground chromed contact surfaces

Simple and immediate positioning of tools with reference to the cutting point, by means of pivoting rings with decimal indication(Scm exclusive solution) complete with diamond cutters

- High rigidity and stability steel monoblock base

- Anti-scratch phenolic multilayer work table with modular holes complete with supports for the panels support to guarantee no risk of damaging the moving panels

- Trimming unit with two 0,55 kW motors with support carriages running on ground guides. Manual device for moving the two motors apart vertically in order to facilitate the insertion of curved panels

Horizontal and vertical adjustments of the upper motor respectively to trim panel with chamfered edge and to adjust the position according to the panel thickness.

Integrated exhaust outlets to ensure a clean work table at all times without

hampering the machining

Pneumatic heads opening with pedal control - 200 Hz Inverter for the best finishing on all edege types; complete with electronic brake.

- Front extension for the support of large dimensioned panels

- Wheels to allow machine movement

*Does not include power cable

MACHINE CONFIGURATION

(Options and accessories included with this machine)

- Pneumatic heads opening with pedal control

- Front extension for the support of large dimensions panels

- Wheels to allow machine movement

TECHNICAL FEATURES | ||

Panel thickness | mm (in) | 14-80 (0.56” – 3.12”) |

Max. edge thickness | mm (in) | 4 (0.19”) |

Minimum panel width | mm (in) | 100 (3.94”) |

Minimum panel length | mm (in) | 200 (7.87”) |

Minimum internal radius | mm (in) | 25 (0.94”) |

Variable cutters speed | rpm | 9.000 – 15.000 |

MINIMUM INSTALLATION REQUIREMENTS | ||

Compressed air consumption | l/min | 3,5 |

Exhaust air consumption | m³/h (CFM) | 720 (424) |

Installed motor power | kW | 1,5 |

USA Version -Voltage /Frequency | 230V – 60Hz |

For any questions concerning delivery, please contact eshopsupportca@scmgroup.com

To ensure a clear and hassle-free purchasing experience, below are the weight and dimensions of the packaged machine at the time of delivery:

| Dimensions | ||

| Lenght | cm (in) | 100 (40) |

| Width | cm (in) | 104 (41) |

| Height | cm (in) | 150 (60 ) |

| Weight | kg (lb) | 217 (479) |

Before completing the purchase, the customer will choose the following delivery option:

Dedicated Courier Delivery (Incoterm DAP - Delivered at Place)

By selecting this option, SCM will entrust delivery to a specialized carrier, ensuring safe transportation handled by professionals. The service includes:

- Advance phone notice before delivery

- Hydraulic tail lift for unloading the machine from the truck

Important: Deliveries are made exclusively to the curbside, meaning the machine will be dropped off at the entrance of the building or designated location. Internal transport and positioning inside the premises are not included. If a forklift or other equipment is needed for internal movement, the customer is responsible for arranging these operations.

If the machine is purchased with installation service, after the order is completed, SCM Service or an authorized center will contact the customer to coordinate: the date of installation, equipment needed, and documentation required for installation.

SCM Group Canada is not responsible for any damages, injuries, or losses resulting from improper installation, unsafe or incorrect use of the machine, failure to follow the manufacturer’s guidelines, or any modifications made by the customer or third parties.

Customers who choose to opt out of professional installation assume full responsibility for ensuring that the machine is installed and operated in strict accordance with the provided instructions and safety standards. If you have not received the user manual, please contact servicecanada@scmgroup.com with the machine’s serial number to obtain it before installation and use.

SCM Group Canada disclaims all liability for any accidents, malfunctions, or consequential damages resulting from non-compliance with these guidelines.

Installation & Warranty Activation

If installation is not included in your purchase and you would like to have the machine installed by our technicians, please contact servicecanada@scmgroup.com or call 437-335-6781 (Monday to Friday, 7:30 AM – 4:30 PM EST) for assistance.

If SCM installation is not required, you must complete and submit the warranty activation form (VICA) to servicecanada@scmgroup.com within 10 business days from the machine’s delivery date. The form will be provided with the purchase order confirmation or can be requested by contacting us. Failure to submit the form on time may result in the warranty being voided.