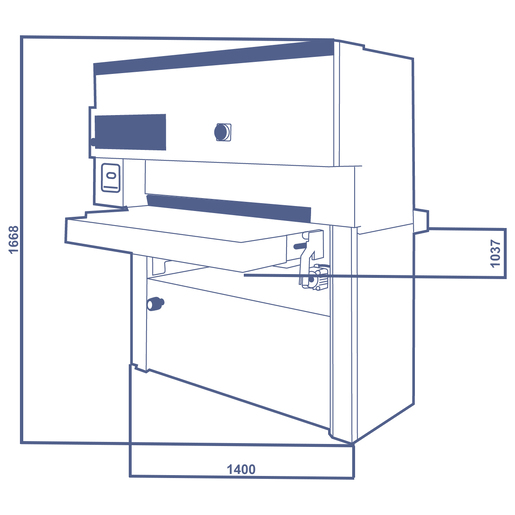

dmc sd 10 Automatic wide belt sander with combined unit (CS 95 version)

C$27,700.00

(Taxes not included)

dmc sd 10, automatic wide belt sander perfect for the craftsman who demands precision when calibrating and superior finishing quality.

Sturdy and ergonomic steel main frame with reduced dimensions and no obstacles on the ground for the best space optimization. The optimization also concerns the sd 10 set-up time which are reduced due to the electronic positioner of the working thickness. While the natural rubber belt delivers a continuous panel grip for maximum steadiness during sanding process.

Finally, the roller and pad on/off features present in the "CS unit" enable multiple processing: from the solid wood panel to the veneered one, up to knotted solid wood calibrating operations.

*Photos may include optional equipment. Please verify availability and compatibility under Product Details and Specs.

Item currently not available

Automatic platen positioner with automatic detection of workpiece thickness for consistently accurate machining with no risk of operator error.

Compact to leave you more space. The machine's small footprint simplifies their placement while maintaining the machine's performance and production potential.

Rhombus carpet: provides the best traction for the workpiece, and the larger surface area also ensures its stability.

- 85 Sh Grooved rubber-coated calibrating roller to deliver excellent finishing results when calibrating knotted solid wood or with cross grain, without requiring any maintenance;

- Semi-stiff pad for veneered panel sanding;

- Two idle roller conveyor at the working table infeed and outfeed permit to resist heavy working loads;

- Electronic positioning device for a precise and fast working table opening.

- Electronic readout of working thickness in inches

*Does not include power cable

MACHINE CONFIGURATION

(Options and accessories included with this machine)

- "TSP/I" Semi-stiff flat pad

- Automatic start-delta-start on main motor

- 2 infeed support rollers and two outfeed support rollers

- Electronic positioning for working table

- Electronic readout in "inches"

- Main motor 11 kW (15 hp)

| TECHNICAL FEATURES | ||

| Working width | in | 37” |

| Min/max machining thickness | in | 0.16” – 6.7” |

| Sanding belt width | in | 38” |

| Abrasive belts length | in | 60” |

| Main motor power | kW (Hp) | 11 (15) |

| Feed belt motor power | kW (Hp) | 0.3 / 0.55 (0.4 / 0.7) |

| Fed belt speed | ft/min | 15 or 30 |

| MINIMUM INSTALLATION REQUIREMENT | ||

| Compressed air consumption | [cfm] | 0.7 |

| Extraction air consumption | [cfm] | 718 |

| Exhaust air speed | [ft/sec] | 72 |

| Installed motor power | [kVA] | 16.5 |

| Canada Version Voltage /Frequency | [V] – [Hz] | 600 - 60 |

For any questions concerning delivery, please contact eshopsupportca@scmgroup.com

To ensure a clear and hassle-free purchasing experience, below are the weight and dimensions of the packaged machine at the time of delivery:

| Dimensions | ||

| Lenght | cm (in) | 143 (57) |

| Width | cm (in) | 115 (46) |

| Height | cm (in) | 180 (71 ) |

| Weight | kg (lb) | 692 (1526) |

Before completing the purchase, the customer will choose the following delivery option:

Dedicated Courier Delivery (Incoterm DAP - Delivered at Place)

By selecting this option, SCM will entrust delivery to a specialized carrier, ensuring safe transportation handled by professionals. The service includes:

- Advance phone notice before delivery

- Hydraulic tail lift for unloading the machine from the truck

Important: Deliveries are made exclusively to the curbside, meaning the machine will be dropped off at the entrance of the building or designated location. Internal transport and positioning inside the premises are not included. If a forklift or other equipment is needed for internal movement, the customer is responsible for arranging these operations.

If the machine is purchased with installation service, after the order is completed, SCM Service or an authorized center will contact the customer to coordinate: the date of installation, equipment needed, and documentation required for installation.

SCM Group Canada is not responsible for any damages, injuries, or losses resulting from improper installation, unsafe or incorrect use of the machine, failure to follow the manufacturer’s guidelines, or any modifications made by the customer or third parties.

Customers who choose to opt out of professional installation assume full responsibility for ensuring that the machine is installed and operated in strict accordance with the provided instructions and safety standards. If you have not received the user manual, please contact servicecanada@scmgroup.com with the machine’s serial number to obtain it before installation and use.

SCM Group Canada disclaims all liability for any accidents, malfunctions, or consequential damages resulting from non-compliance with these guidelines.

Installation & Warranty Activation

If installation is not included in your purchase and you would like to have the machine installed by our technicians, please contact servicecanada@scmgroup.com or call 437-335-6781 (Monday to Friday, 7:30 AM – 4:30 PM EST) for assistance.

If SCM installation is not required, you must complete and submit the warranty activation form (VICA) to servicecanada@scmgroup.com within 10 business days from the machine’s delivery date. The form will be provided with the purchase order confirmation or can be requested by contacting us. Failure to submit the form on time may result in the warranty being voided.