minimax cu 410c Universal combined machine

A$21,698.00

(Price does not include taxes, shipping and installation)

The universal combined machine cu 410c is the machine with the largest useful working width at the planer, 410mm in the field of multifunctional joinery machines. Among the most important aspects, in order to ensure precision and reliability, there is the extremely efficient exhaust hood, which, by ensuring a clean machine environment, facilitates its maintenance and increases the machine precision and reliability overtime.

*Photos may include optional equipment. Please verify availability and compatibility under Product Details and Specs.

An incredible cutting with the saw unit with 315 mm maximum blade (not included) diameter with the scoring blade installed

Large squaring frame with professional telescopic swinging arm support

Thicknessing is more comfortable: during the changeover from surfacing to thicknessing the surfacing tables open towards the inside of the machine, with a 90° angle, and simultaneously.

The “Xylent” spiralknives cutter block gives an exceptional finish with reduced noise during machining thus to provide a more comfortable working environment

SCM Thundercut App for tablet: cutting optimizer and sequencer even for less experienced operators

- Very high effective saw unit exhaust hood: the emission level is 90% lower with respect to the maximum level allowed by the European safety regulations!

- The scoring unit adjustment is carried out from outside the machine by means of with special knobs and without the necessity of keys

- The sliding carriage ensures top quality precision, smooth and silent action, self cleaning dustproof system, long lasting accuracy, no adjustments required

- The telescopic squaring rule is equipped with 2 flip-over stops which allow to have precise references that can be used for both profiles.

- For an impeccable result, the pressure of the thicknesser feed rollers can be adjusted according to the type of wood

- The thicknesser infeed roller has helical toothing to guarantee strong, constant work piece feed.

- The sandblasted steel outfeed roller maintains the perfect post-machining finish.

- Professional fences are supplied for the saw and surfacing planer. The fences are designed to be easy to remove and to allow a rapid changeover from one type of operation to another

- The spindle moulder unit has a cast iron structure and it is closed off by a cast iron “cup” to protect mechanical components inside the machine from sawdust, shavings and dirt.

- Precise and safe machining with the spindle moulder fence with micrometric adjustment complete with vertical and horizontal presser

- 2 extra handwheels for an easy operating units movement

- Anodized aluminum tables for spindle moulder fence

- Exhaust outlet under the worktable

- Spindle moulder with Interchangeable spindle for a very quick spindle substitution

- Wheels for an easy machine movement

MACHINE CONFIGURATION

(Options and accessories included with this machine)

- minimax cu 410c CE version

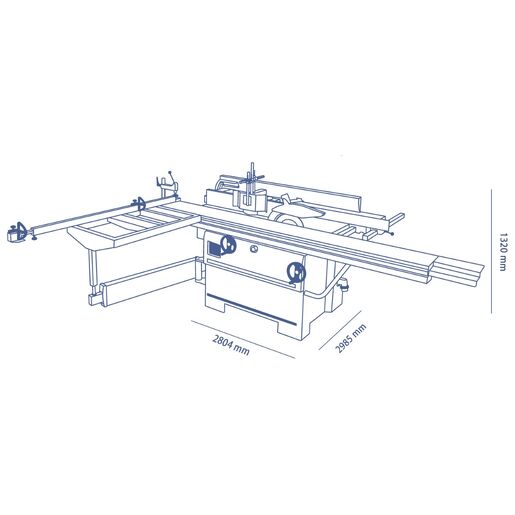

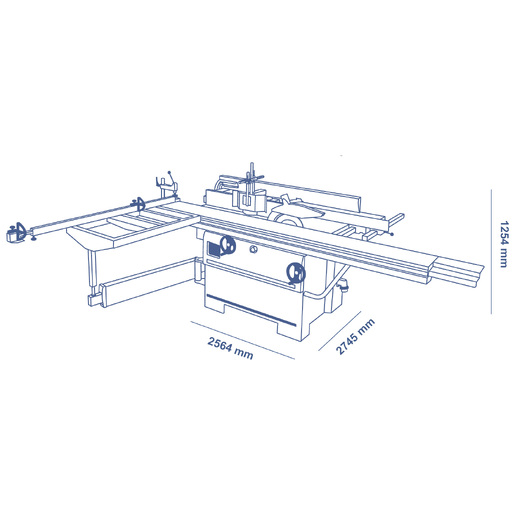

- Version with maximum squaring stroke 2600 mm

- Belt driven scoring unit complete with blade

- 2 extra handwheels for the operating units movement

- Professional fences

- "Xylent" spiralknife cutterblock with 3 series of knives

- Anodized aluminium tables for spindle moulder fence

- Exhaust outlet under the worktable

- Wheels for machine movement

- Interchangeable spindle

- Spare spindle for router bits each

- Spindle moulder shaft of 30 mm diam

- Locking by countersunk socket screw

TECHNICAL FEATURES | ||

Planer: | ||

Useful working width | [mm] | 410 |

Cutter block diameter | [mm] | 72 |

Maximum stock removal | [mm] | 4 |

Surfacing tables total length | [mm] | 1800 |

Thicknessing table dimensions | [mm] | 605 x 410 |

Feed speed on thicknesser | [m/min] | 7 |

Minimum ÷ maximum working height on thicknesser | [mm] | 3 ÷ 230 |

Circular saw: | ||

Cast iron saw-spindle moulder worktable dimensions | [mm] | 1115 x 335 |

Blades tilting | 90° ÷ 45° | |

Maximum saw blade diam. with scoring blade installed | [mm] | 315 |

Maximum saw blade projection from table at 90°/45° | [mm] | 100/78 |

Maximum squaring stroke | [mm] | 2600 |

Cutting width on parallel fence | [mm] | 900 |

Spindle moulder: | ||

Spindle diameter | [mm] | 30 |

Max. useful spindle length | [mm] | 100 |

Spindle moulder speed | [rpm] | 3500/7000/10.000 |

Max. tool diameter when profiling | [mm] | 210 |

Max. diam. of tool lowered under the table at 90° | [mm] | 180 |

Other technical features: | ||

Three-phase motors | kW/hp/Hz | 5/6,6/50 |

Exhaust outlets diameter | [mm] | 120 |

INSTALLATION REQUIREMENTS | ||

Electrical cable section | [mm2] | 2,5 |

Power absorption | [A] | 9 |

CE version - voltage - frequency | 400EU - 50Hz |