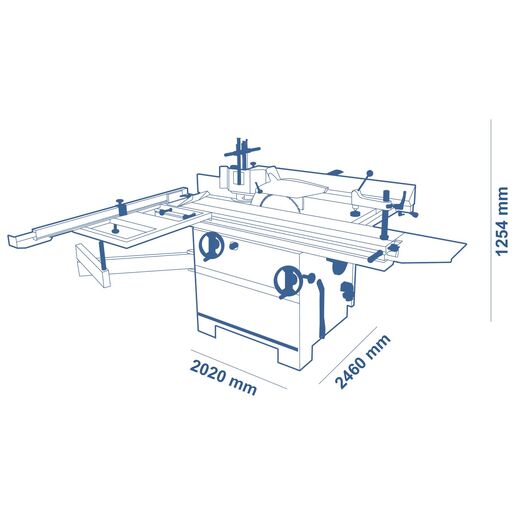

minimax lab 300p Universal combined machine

£10,036.00

(Price does not include VAT and delivery)

Experience woodworking excellence with the minimax lab 300p universal combined machine. Designed for professional crafts workshops, it offers precision and efficiency. Featuring user-friendly elements like an inward-opening surfacing worktable and anodized-extruded guides, it ensures smooth operation. Enjoy adjustable speeds on the spindle moulder unit, a tiltable saw unit with a sliding aluminum carriage, and safety features such as CE-approved shaft protection. Unleash your woodworking passion with this all-in-one solution, delivering precision, versatility, and reliability.

Spindle moulder with superior performance

90° tables opening towards the inside of the machine: exceptional access

Incredible cutting with the new saw unit and sliding table

- Very high effective saw unit exhaust hood: the emission level is 90% lower with respect to the maximum level allowed by the European safety regulations!

- The sliding carriage ensures top quality precision, smooth and silent action, self-cleaning dustproof system, long lasting accuracy, no adjustments required.

- The Tersa cutterblock with automatic knives clamping by means of the centrifugal force ensures safe and precise machining. The system, without fixing screws, makes knives substitution extremely fast

- Handwheel with gravitational numerical readout for an easy and precise positioning of the thicknessing table

- The spindle moulder unit has a cast iron structure and it is closed off by a cast iron “cup” to protect mechanical components inside the machine from sawdust, shavings and dirt.

- Precise and safe machining with the spindle moulder fence with micrometric adjustment complete with vertical and horizontal pressers

- Professional fences are supplied for the saw and surfacing planer. The fences are designed to be easy to remove and to allow a rapid changeover from one type of operation to another

- 2 extra handwheels for the operating units movement

- Saw unit with scoring blade (option) installed (blade not included)

MACHINE CONFIGURATION

(Options and accessories included with this machine)

- Belt driven scoring unit complete with blade

- Professional fences

- Handwheel with gravitational numerical readout for the thicknessing table positioning

- 2 extra handwheels for the operating units movement

- 2 squaring flip-over stops

- "Tersa" cutterblock Ø 72 mm with 3 knives with rapid locking system

- Electric pre-setting (CE and USA-Canada versions) and flip over support for feeder

- 3 single-phase motors 2,2kW (3hp) 50Hz

- Spindle moulder shaft of 30 mm diam.

- Locking by countersunk socket screw

| TECHNICAL FEATURES | ||

| Planer: | ||

| Useful working width | [mm] | 300 |

| Cutter block diameter (mm)/n. standard knives | 72/3 | |

| Standard knives dimensions | [mm] | 300 x 30 x 3 |

| Max. stock removal | [mm] | 3 |

| Surfacing tables total length | [mm] | 1300 |

| Thicknessing table dimensions | [mm] | 450 x 300 |

| Feed speed on thicknesser | [m/min] | 7 |

| Min. ÷ max. working height on thicknesser | [mm] | 3 ÷ 220 |

| Circular saw: | ||

| Cast iron saw-spindle moulder worktable dimensions | [mm] | 1020 x 325 |

| Blades tilting | 90° ÷ 45° | |

| Max. saw blade Ø with scoring blade installed | [mm] | 315 |

| Max. saw projection from table at 90°/45° | [mm] | 100/78 |

| Maximum squaring stroke | [mm] | 1600 |

| Cutting width on parallel fence | [mm] | 800 |

| Spindle moulder: | ||

| Max. useful spindle length | [mm] | 100* |

| Spindle moulder speeds (at 50 Hz) | [rpm] | 3500/7500/10.000 |

| Max. tool diameter when profiling | [mm] | 210 |

| Max. Ø of tool lowered under the table at 90° | [mm] | 180 |

| Other technical features: | ||

| 3 single-phase motors S6 | 2,2kW (3hp) 50Hz | |

| Exhaust outlets diameter | [mm] | 120 |

| Spindle moulder available with following diameters: | 30 - 32 - 35 - 40 - 50 mm, 3/4" - 1" - 1 1/4" | |

| * 70 mm with 3/4” spindle |