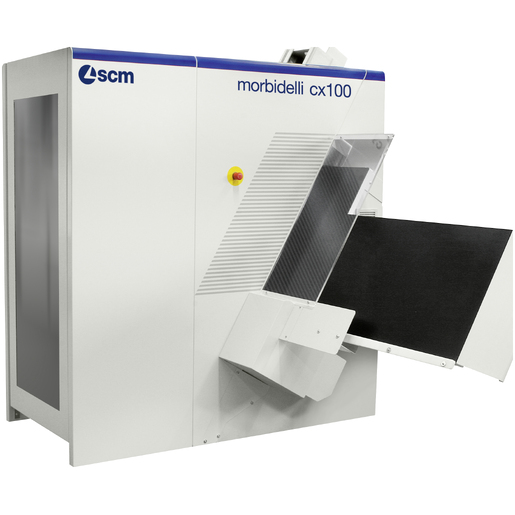

morbidelli cx100 CNC drilling and grooving centre

$90,599.00

(Price does not include taxes, shipping and installation)

The morbidelli CX100 is a compact vertical cnc machining center for wood panels. This high-performance drilling and routing machine can process up to 400 panels per shift, even though it only occupies 8m2 (<100 ft2) of floorspace. A primary working unit equipped with 18 independently fired drills guarantees repeated accuracy and precision on 5 sides of the panel due to the SCM patented Ro.Ax (Roto-Axial) drilling head design. An on-board 3-axis router and integrated grooving blade expand the capabilities of the cx100, ensuring that any additional processing of machined panels is reduced. The feed-thru clamp design ensures that this technology can be used for any batch size since the setup time between panels is zero. The CX100 is ergonomically comfortable to reload and because it is controlled by SCM’s Maestro Software Suite the operator will be assured a powerful and user-friendly HMI experience.

*Photos may include optional equipment. Please verify availability and compatibility under Product Details and Specs.

The highest performance drilling technology on the market is installed with the Ro.Ax (Roto-Axial) F18L drilling unit from Hiteco. Fewer and larger internal components mean the head can drill faster and more accurately and requires 10X less maintenance than other units. An inverter is included to boost drilling speeds up to 8,000rpm

Each panel can be automatically measured to check for variance in the length and width, eliminating the possibility of erroneous positioning of the machining operations on the finished panel

Made possible by the clamp holding design and the vertical worktable, the machine requires no operator intervention between batch 1 panels to set up the machine

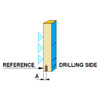

The highest quality of finished casegoods is maintained through intelligent design of the CX100. By drilling and routing on the top face of the panel any variance in panel thickness is disguised on the finished product

- Hiteco 4.5 kW (6HP) Electrospindle for routing operations,capable of speeds up to 24,000 rpm and featuring HSK63F tool attachment with rapid tool change.

- An integrated photocells safety system to guarantee maximum operator safety.

- Self-adjusting movable clamp for 10-60mm (.4”-2.3”) thicknesses.

- Axes movement on prismatic linear guides and recirculating ball bearings.

- Side supports for machining of long workpieces.

- Brushless motors for high precision and movement speed up to 40m/min.

- Maestro Active CNC CAD/CAM software application designed and developed entirely by SCM in the Windows® environment that allows for easy programming of parts.

- Control console with "eye-M" integrated PC connected to the CNC machine which allows the use of the factory software. A 21,5” LCD multi-touch color display, extended keyboard and comfortable support for the mouse create a comfortable and ergonomic experience for the operator.

- An additional key for Maestro CNC CAD/CAM software is included for use on an office computer to alleviate the requirement to program at the machine.

*Does not include power cable

| TECHNICAL FEATURES | ||

Max. panel dimensions | mm (in) | 3050x900x60 (120.0”x35.4”x2.3”) |

| Min. panel dimensions | mm | 200x70x10 |

| X-Y axes speed | m/min (ft/min) | 40 (1,575) |

| RO.AX DRILLING UNIT | ||

| Connection tools with cylindrical shank, | Ø mm | 10 |

| Max. tools diameter | mm (in) | 70 (2.75”) |

| Vertical spindles | n. | 12 (7X-5Y) |

| Horizontal spindles | n. | 2+2 (X) 2(Y) |

| Rotating spindles motor power | kW/Hp | 2,2/3 |

| Spindles speed | rpm | 3000-8000 |

| Fixed integrated disc cutter (direction) | X | |

| Max. diameter of disc cutter | mm (in) | 125 (4.9”) |

| Disc cutter rotating speed | rpm | 5.500 |

| ELECTROSPINDLE | ||

| Motor power (S6) | kW | 4,5 |

| Max. speed. | rpm | 24.000 |

| Manual tool changer | HSK63F | |

| Max. tool diameter | mm (in) | 20 (0.78”) |

| MINIMUM INSTALLATION REQUIREMENTS | ||

Compressed air consumption | Nl/cycle | 450 |

| Extraction air consumption | m³/h | 1900+550+300 |

| Exhaust air speed | m/sec | 30 |

| Installed motor power | kVA | 21 |

| Exhaust outlet diameter | mm | 150+80+60 |

| Usa- Canada Version Voltage /Frequency | 230V – 60HZ |

For any questions concerning delivery, please contact eshopsupportus@scmgroup.com

To ensure a clear and hassle-free purchasing experience, below are the weight and dimensions of the packaged machine at the time of delivery:

| Dimensions | ||

| Lenght | in | 80 |

| Width | in | 87 |

| Height | in | 89 |

| Weight | lb | 3280 |

Before completing the purchase, the customer can choose between two delivery options:

1 - Pickup from Our Warehouse (Incoterm EXW - Ex Works)

The machine can be picked up personally from our warehouses. Prior to purchase, verify in which locations this unit is available.

2 - Delivery by Dedicated Freight Carrier (Incoterm DAP - Delivered at Place)

By selecting this option, SCM will entrust the delivery to a specialized freight carrier, ensuring secure transport managed by professionals. The service includes:

- Advance phone notice before delivery

Important: Due to the size of the machine, unloading from the truck is the customer’s responsibility. A forklift or appropriate equipment will be required to safely complete the unloading process. Internal transport and positioning inside the premises are not included.

If the machine is purchased with the installation service, after the order is completed, SCM Service or an authorized center will contact the customer to coordinate: the installation date, the necessary equipment, he required documentation for installation.

SCM Group US is not responsible for any damages, injuries, or losses resulting from improper installation, unsafe or incorrect use of the machine, failure to follow the manufacturer’s guidelines, or any modifications made by the customer or third parties.

Customers who choose to opt out of professional installation assume full responsibility for ensuring that the machine is installed and operated in strict accordance with the provided instructions and safety standards. If you have not received the user manual, please contact us with the machine’s serial number to obtain it before installation and use.

SCM Group US disclaims all liability for any accidents, malfunctions, or consequential damages resulting from non-compliance with these guidelines.

Installation & Warranty Activation

If installation is not included in your purchase and you would like to have the machine installed by our technicians, please contact us.

If SCM installation is not required, you must complete and submit the warranty activation form (VICA) within 10 business days from the machine’s delivery date. The form will be provided with the purchase order confirmation or can be requested by contacting us. Failure to submit the form on time may result in the warranty being voided.

For any further information or assistance, please feel free to contact us.