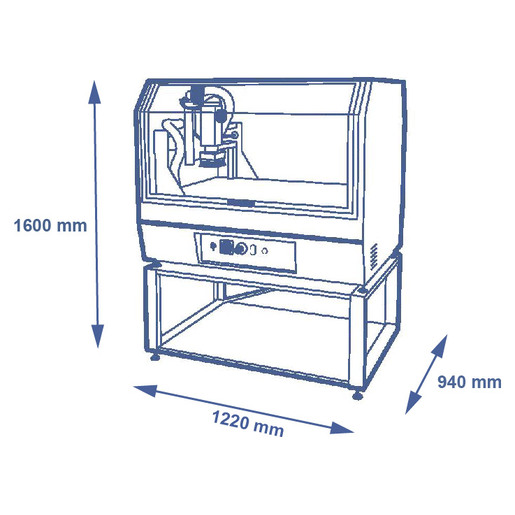

startech cn k Compact 3-axis machining centre

30% Stock Clearance

$9,082.50(Price does not include taxes, shipping and installation)

startech cn k is the new 3-axis machining centre designed for the artisan carpentry, training schools and prototyping departments of industrial realities. It is able to carry out all types of milling, decorations, engraving,signboard creation and 3D model prototyping.

Thanks to its ease of set up and use it can also be installed independently Designed with the highest safety standards in mind, startech cn k is the only one in its category equipped with an integral cabin with internal LED lighting, which ensures absolute protection for the operator and keeps the surrounding environment clean.

The extremely rigid and robust structure guarantees professional precision and repeatability.

*Photos may include optional equipment. Please verify availability and compatibility under Product Details and Specs.

Add a 4th interpolating axis to your cart for only $1!

Maximum safety with the integral cabin that ensures operator protection and keeps the working environment clean

Unique in its category with the 2,2 kW S6 (18000/24000 rpm) powerful electro-spindle with R25 tool-chuck generally used on higher-segment machines

Easy programming with the “open” virtual human-machine interface capable of importing G-code from any type of CAD / CAM software.(it is advisable to verify with the software supplier that the CAD/CAM provides a G-code that can be read from the interface).

- Integral protection cabin with plexiglass front door (unique in its category)

- NC mouvement with 3 interpolating axes

- Ethernet port for user PC connection (PC not included)

- Aluminum work table with "T" grooves

- Internal LED lightening

- HICAM2 virtual human-machine interface

- Support base with wheels and adjustable feet (500 mm height) for an easy machine handling

- Kit of 5 pneumatic suction cups that can be positioned on the work table to assure ease-of-use and accuracy

- Tool height detection sensor for an absolute reliability

*Does not include power cable

MACHINE CONFIGURATION

(Options and accessories included with this machine)

- Machine support base with wheels and adjustable feet (500 mm height)

- Kit of 5 pneumatic suction cups that can be positioned on the work table

- Tool height detection sensor

| TECHNICAL FEATURES | ||

| Work table dimensions | mm | 1170x760 (46"x30") |

| "T" groove dimensions | mm | 13.5x7 opening 8.5 for passage of M8 screw or nut |

| X-Y-Z strokes | mm | 915-610-176(36"-24"-6.9") |

| Z work piece clearance | mm | 160 (6.3") |

| X-Y-Z max. axis stroke | m/min | 5-5-2,5 |

| Min. distance of the spindle ring from the work table | mm | 10 (0.3") |

| Hiteco electro spindle motor power | kW | 2.4 S6 a 300Hz |

| Max. rotating speed | rpm | 24,000 |

| Tool chuck | R25 | |

| Max. tool holder diameter | mm | 16 (0.6") |

| Max. tood diameter | mm | 60 (2.3") |

| INSTALLATION REQUIREMENTS | ||

| Power supply | V (Hz) | 230 (50) single phase |

| Rated current | A | 16 (0.6") |

| Extraction air consumption | m3/h | 115 |

| Exhaust aid speed | m/s | 20 |

| Exhaust outlet diameter | mm | 40 (1.6") |

| Compressed air consumption | NI/min | 120 |

| Pneumatic system operating pressure | bar | 6.5 |

For any questions concerning delivery, please contact eshopsupportus@scmgroup.com

To ensure a clear and hassle-free purchasing experience, below are the weight and dimensions of the packaged machine at the time of delivery:

| Dimensions | ||

| Lenght | in | 48 |

| Width | in | 52 |

| Height | in | 48 |

| Weight | lb | 620 |

Before completing the purchase, the customer can choose between two delivery options:

1 - Pickup from Our Warehouse (Incoterm EXW - Ex Works)

The machine can be picked up directly from our warehouses. Prior to purchase, verify in which locations this unit is available.

2 - Delivery by Dedicated Freight Carrier (Incoterm DAP - Delivered at Place)

By selecting this option, SCM will entrust the delivery to a specialized freight carrier, ensuring secure transport managed by professionals. The service includes:

- Advance phone notice before delivery

- Hydraulic tail lift for unloading the machine from the truck

Important: Deliveries are made exclusively to the curbside, meaning the machine will be dropped off at the entrance of the building or designated location. Internal transport and positioning inside the premises are not included. If a forklift or other equipment is needed for internal movement, the customer is responsible for arranging these operations.

If the machine is purchased with the installation service, after the order is completed, SCM Service or an authorized center will contact the customer to coordinate: the installation date, the necessary equipment, he required documentation for installation.

SCM Group US is not responsible for any damages, injuries, or losses resulting from improper installation, unsafe or incorrect use of the machine, failure to follow the manufacturer’s guidelines, or any modifications made by the customer or third parties.

Customers who choose to opt out of professional installation assume full responsibility for ensuring that the machine is installed and operated in strict accordance with the provided instructions and safety standards. If you have not received the user manual, please contact us with the machine’s serial number to obtain it before installation and use.

SCM Group US disclaims all liability for any accidents, malfunctions, or consequential damages resulting from non-compliance with these guidelines.

Installation & Warranty Activation

If installation is not included in your purchase and you would like to have the machine installed by our technicians, please contact us.

If SCM installation is not required, you must complete and submit the warranty activation form (VICA) within 10 business days from the machine’s delivery date. The form will be provided with the purchase order confirmation or can be requested by contacting us. Failure to submit the form on time may result in the warranty being voided.

For any further information or assistance, please feel free to contact us.