nova si 400ep Circular saw with tilting blade

C$39,700.00

(Shipping included, taxes not included)

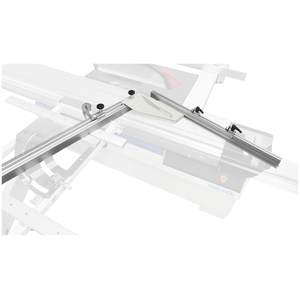

Smooth sliding and a solid work surface. The wide section of the carriage, with closed reticular geometry provides extreme rigidity and minimum deflection. A smooth operating motion is guaranteed over time by the system of sliding bearings running on hardened steel guides using an exclusive method of mechanical fixing.

*Photos may include optional equipment. Please verify availability and compatibility under Product Details and Specs.

Available 1

Item ready for delivery

The saw blade lifting of the saw unit is carried out by a sturdy cast-iron structure with sliding on ground round slideways which guarantee the best accuracy. The unit tilting is carried out on cast-iron rotation sectors in a crescent shape to ensure reliability over time

Optimal support also to larger pieces, with the sliding table 360 mm (14.19”) wide. The carriage sliding system is guaranteed for 10 years: a proof of reliability and technology without comparisons

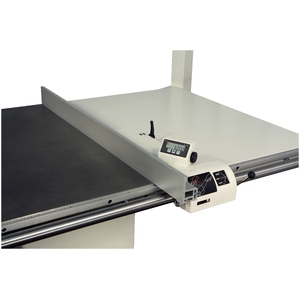

READY: the practical advantage for automatic control of the main positions. The programming of the work becomes simple and effective with the electronic control with a 4” LCD colour screen

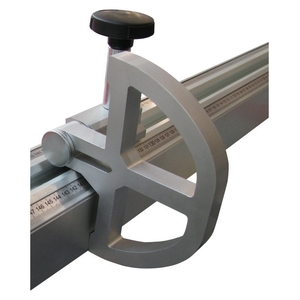

Panel loading is easy on the large squaring frame with an idle roller at the end. The telescopic squaring fence with inclined metric scale and two reversible stops can be used to square panels measuring 3200 x 3200 mm (125.94” x 125.94”) and for miter cuts at up to 45° on both sides of the frame

SCM Thundercut App for mobile devices: optimizer/sequencer even for not skilled workers

- Maximum torsional rigidity and total absence of vibration through the closed loop structure of the saw unit which ensures perfect alignment of the blades during tilted and difficult cuts

- The saw blade uses 100% of the motor power, thanks to the scoring blade with an independent motor

- Vertical and horizontal adjustments of the scoring unit are carried out by user-friendly mechanical levers that operate directly making precise and smooth movements. The useful mechanical stops allows immediately finding of the set position

- The machine is provided with a 120 mm (4.75”) diameter, manually expandable scoring blade with variable thickness from 2,8 to 3,6 mm (0.12”) for the maximum versatility

- The guides of the sliding table are secured with a procedure of aluminium riveting, so that to ensure an exceptional precision and smoothness

- The telescopic squaring fence has two reversible stops with electronic readouts so that they’re position can be easily read even from distance, for an absolute precision and a constant control

- The rip fence, sliding on a sturdy round steel bar, is motorized and programmable through the Ready control panel. The position readout is on magnetic band. All of this for the maximum precision, practicality and ease-of-use.

- The Ready control panel is located on an upper overhead console, in an ergonomic position

*Do not include power cable

MACHINE CONFIGURATION

(Options and accessories included with this machine)

- "READY 3 UP" version

- Squaring fence with no. 2 LCD readouts for stops position

- Device for angular cutting

- Eccentric clamp

TECHNICAL FEATURES | ||

Blades tilting | 90° ÷ 45° | |

Max. saw blade diam. with scoring blade installed | [mm] | 400 (15.75”) |

Max. saw blade projection from table at 90°/45° | [mm] | 140/97 (5.5”/3.81”) |

Scoring blade diameter | [mm] | 120 (4.75”) |

Squaring stroke | [mm] | 3200 (125.94”) |

Cutting width on parallel fence | [mm] | 1270 (49.94”) |

Other technical features: | ||

Three-phase motor | 8kW (11hp) 60Hz | |

Exhaust outlets diameter | [mm] | 120 (4.75”) |