minimax si x Circular saw with ±46° double tilting blade

$27,775.00

(Price does not include taxes, shipping and installation)

Finally available at everybody’s reach. With powered and programmed sawblade movement available as standard.

It allows simultaneous use of a 400mm saw blade and 160mm scoring blade both for 90° cutting and ±46° tilted cutting, guaranteeing the maximum cutting height on veneered panels and solid wood.

*Photos may include optional equipment. Please verify availability and compatibility under Product Details and Specs.

Double tilting at everybody's reach. New saw unit with a stiff cast-iron structure which can accommodate a blade of 400 mm diameter with scoring blade mounted. It ensure a perfect and easy cutting of veneer panels and thick solid wood material with very high thickness both at 90° and tilted cuts at ±46

Unrivalled cutting finishing. Optimal support also to larger pieces, with the new sliding table 360 mm wide. Exceptional precision and smoothness: to secure the guides it is not used glue, since the thickness could affect sliding. They are secured with a procedure of aluminum riveting.

Panel loading is easy on the large squaring frame with an idle roller at the end. The telescopic squaring fence with the inclined metric scale and two reversible stops can be used to square panels measuring 3200 x 3200 mm and for tilted cuts at up to 45° on both sides of the frame

Programmed movement - 3 NC axes. The “READY3” control panel manages the powered and programmed movement of the saw blade unit and rip fence, increasing productivity and working quality.

SCM Thundercut App for mobile devices: optimizer/sequencer even for not skilled workers

STANDARD EQUIPMENT

- Cast iron saw unit, with lifting system by means of cylindrical bars and tilting on high rigidity sliding side trunnions

- Scoring unit with independent motor and external setting up

- Anodized aluminum alloy carriage (dimensions 3200 x 360 mm) sliding on hardened steel guides, which are fixed on the carriage by means of mechanical bending system

- Squaring frame (dimensions 1200 x 650 mm) complete with:

- telescopic fence with 2 flip-over stops and rule tilted towards the operator

- eccentric clamp

- swinging arm support

- idle roller to facilitate the panel loading/unloading

- "READY 3UP" electronic control

Overhead mobile panel to control 3 axes: blade unit lifting/tilting and rip fence position

Additional functions:

- Tools data setting with automatic height adjustment in respect to the blade angle

- Mode: manual, semiautomatic and automatic

- memory capacity up to 99 programs

Rip fence details:

- position readout on encoder

- adjustment by means of recirculating ball screws

- continuous adjustments by means of pushbuttons or automatic positioning

- possibility of incremental positioning

- possibility of fence exclusion

- Optimizer/Sequencer App for Tablet: SCM Thundercut

Application to be downloaded from the App Store or Paly Store on compatible tablets (mobile devices) equipped with iPadOS or Android operating systems.

It can be activated using the QR code supplied with the machine. The App allows to:

- manage your machine stock and the material and panel magazine

- create and modify projects, import projects from the main furniture design software ("cpout" file format), import cutting lists

- optimize cutting lists, choosing from one or more proposals of the optimization software integrated into the App

- set the machine correctly for each cut to be made, thanks to the simple and intuitive graphics of the 3D sequencer that guides the operator at each step

- print labels with bar code to identify the various parts, thanks to the Bluetooth connection with compatible label printers

SAFETY/PROTECTIONS

- Emergency pushbutton located on the front machine side

- Overhead saw guard with incorporated dust extraction, 80 mm outlet diameter

- Main power switch can be locked in the off position with a padlock

TOOLING INCLUDED

- 1 saw blade 350 mm (57.04.16)

- 1 Expandable scoring blade (R0.00.29)

- Trimming shoe, push stick and push handle

- Toolbox: Wrenches, allen wrenches, user manual, spare parts catalog

MACHINE CONFIGURATION

Options and accessories included in this quotation

- 10.40.50 USA safety regulations version

- R0.00.29 minimax si x Usa/Canada version

Circular saw with tilting blade and devices in conformity with USA and Canada safety regulations, complete with:- self-braking motor

- overhead blades guard

- blade movement with 2-axis control

- 93.07.51 220 volt

- 93.12.15 Frequency 60 hz

- 58.04.90 Version with maximum squaring stroke 3200 mm (10.5’)

- 58.05.46 "READY 3 UP" version

- Mobile upperhead control panel

- Powered control of blades unit lifting/tilting

- Powered parallel fence with electronic programmer

- 58.02.13 Angular cutting device with flip-over stops equipped with:

- telescopic fence with two flip-over stops

- pre-set for angle rapid selection

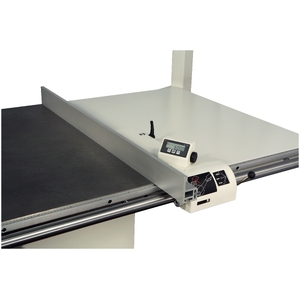

- 58.03.45 Additional table on the sliding table

for the support of panels with large dimensions - 57.04.16 Saw blade 350 mm

- 08.04.95 Crating for version with 3200 mm sliding table

- 10.99.91 Machine language: ENGLISH

*Does not include power cable

TECHNICAL SPECIFICATIONS

| Main blade | Scoring blade |

Motor power | 11 HP - 8 kW | 1.3 HP - 0.9 kW |

Blade speed | 4000 rpm | 6000 rpm |

Max. blade diameter (with scoring blade installed) | 400 mm (15.75”) | 160 mm (6.25”) |

Arbor size | 25.40 mm (1”) | 20 mm (0.79”) |

Diameters to be used simultaneously | mm (in) | 400 x 160 mm (15.69” x 6.25”) |

Blade tilting | -46° ÷ +46° |

|

max. saw blade projection from table at 90° / +46° / -46° with 400 mm blade | 136 / 97 / 60 mm (5.31” / 3.81” / 2.31”) |

|

|

| |

Max. squaring capacity | 3200 mm x 3200 mm (10.5’ x 10.5’) |

|

Ripping capacity on parallel fence | 1270 mm (50”) |

|

worktable dimensions | 1000 x 685 mm (39.31” x 26.94”) |

|

|

|

|

Installation requirements |

|

|

Nominal extraction air consumption | 1647 m3/h (955 CFM) |

|

Air exhaust speed | 20 m/s (66 ft/s) |

|

Exhaust outlets diameter: Frame outlet Overheard protection |

120 mm (4.69”) 80 mm (3.12”) |

|

Electrical requirements *subject to change; must be verified prior to installation* | 220 V – 60 Hz –3phase – 31 A |

|

For any questions concerning delivery, please contact eshopsupportus@scmgroup.com

To ensure a clear and hassle-free purchasing experience, below are the weight and dimensions of the packaged machine at the time of delivery:

| Dimensions | ||

| Lenght | in | 132 |

| Width | in | 54 |

| Height | in | 46 |

| Weight | lb | 2031 |

Before completing the purchase, the customer can choose between two delivery options:

1 - Pickup from Our Warehouse (Incoterm EXW - Ex Works)

The machine can be picked up personally from our warehouses. Prior to purchase, verify in which locations this unit is available.

2 - Delivery by Dedicated Freight Carrier (Incoterm DAP - Delivered at Place)

By selecting this option, SCM will entrust the delivery to a specialized freight carrier, ensuring secure transport managed by professionals. The service includes:

- Advance phone notice before delivery

Important: Due to the size of the machine, unloading from the truck is the customer’s responsibility. A forklift or appropriate equipment will be required to safely complete the unloading process. Internal transport and positioning inside the premises are not included.

If the machine is purchased with the installation service, after the order is completed, SCM Service or an authorized center will contact the customer to coordinate: the installation date, the necessary equipment, he required documentation for installation.

SCM Group US is not responsible for any damages, injuries, or losses resulting from improper installation, unsafe or incorrect use of the machine, failure to follow the manufacturer’s guidelines, or any modifications made by the customer or third parties.

Customers who choose to opt out of professional installation assume full responsibility for ensuring that the machine is installed and operated in strict accordance with the provided instructions and safety standards. If you have not received the user manual, please contact us with the machine’s serial number to obtain it before installation and use.

SCM Group US disclaims all liability for any accidents, malfunctions, or consequential damages resulting from non-compliance with these guidelines.

Installation & Warranty Activation

If installation is not included in your purchase and you would like to have the machine installed by our technicians, please contact us.

If SCM installation is not required, you must complete and submit the warranty activation form (VICA) within 10 business days from the machine’s delivery date. The form will be provided with the purchase order confirmation or can be requested by contacting us. Failure to submit the form on time may result in the warranty being voided.

For any further information or assistance, please feel free to contact us.