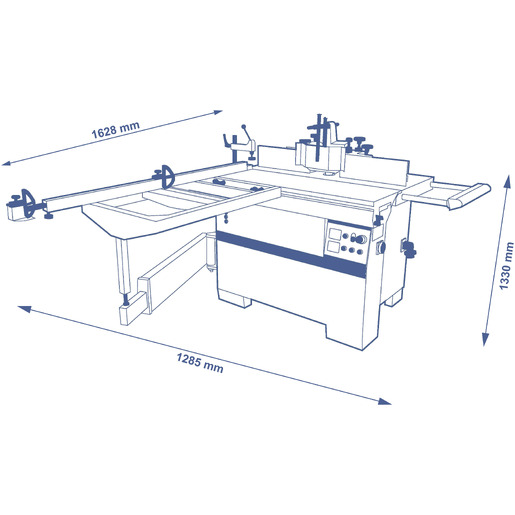

minimax tw 55es Spindle moulder - 3ph

$11,675.00

(Price does not include taxes, shipping and installation)

The minimax tw 55es is a spindle moulder that represents the culmination of years of experience in manufacturing quality solid wood SCM products. This is a 4-speed heavy duty joinery machine and is equipped with both a sliding table and tilting spindle.

The slider has hardened steel guide ways and precision bearings, so it incorporates the exact technology found in our top selling sliding table saws. The hood has memory pins so if removed, it will go right back into the same position, making this shaper accurate and repeatable.

*Photos may include optional equipment. Please verify availability and compatibility under Product Details and Specs.

Maximum stability and rigidity in all working conditions, thanks to a large spindle moulder column made entirely of cast iron.

The spindle moulder hood uses a system for adjusting the guides with a rack and it is fitted with a mechanical digital readout.

Thanks to the system of memories the spindle moulder hood can be removed and repositioned without losing the machining position.

Optimal support also to larger pieces, with the sliding table 360 mm wide. The guides are secured with a procedure of aluminum riveting, so that to ensure an exceptional precision and smoothness.

STANDARD EQUIPMENT

- Extruded anodized aluminum sliding table (dimensions 1200 x 360 mm) sliding on high precision hardened steel guideways, which are fixed by means of mechanical bending system

- Spindle reverse rotation

- Adjustable spindle fence with micrometric adjustment complete with vertical and horizontal pressers

- Handweels with gravitational readouts

- Electric pre-setting for feeder (see electrical requirements)

- Device for angular cutting with 2 flip-over stops and clamp

TOOLING INCLUDED

- Qty. 1 1 ¼” spindle

- Shaper push handle

- Spare belts

- Toolbox: Wrenches, allen wrenches, user manual, spare parts catalog

MACHINE CONFIGURATION

- 10.19.96 USA safety regulations version

- R0.21.88 minimax tw 55es Usa/Canada version

- Shaper with sliding table and fixed or tilting spindle with devices in conformity with USA-Canada safety regulations and complete with:

- self-braking motor

- 93.07.51 220 volt

- 93.12.15 Frequency 60 hz

- 58.10.03 Spindle moulder fence with 3 controlled adjustments

with reference pins for easy re-positioning and numeric readouts for micrometric adjustment

Max. tool diameter: 240 x 85 mm - 58.02.25 Tenoning table and protection hood max. tool Ø 275 mm

- 58.02.26 Tiltable spindle moulder 90° ÷ 45°

equipped with fixed handwheel with gravitational numerical readout of spindle moulder tilting - 13.02.50 Interchangeable spindle

100 mm max. height (70 if 3/4") - 13.13.25 Spindle moulder shaft of 1 1/4"

- 21.13.19 Locking by countersunk socket screw

- 08.09.99 Triple wall

- 10.99.91 Machine language: ENGLISH

*Does not include power cable

| TECHNICAL SPECIFICATIONS | |

| Main motor power | 8 HP - 6 kW |

| max. useful spindle length | 90mm (3.5”)* - 125mm (5”) optional *70mm ( 2.75”) with 3/4" spindle |

| Capacity, under the nut, with interchangeable spindle | 85 mm (3.31”) |

| spindle moulder speeds (at 50 Hz) | 4000 - 7000 - 9000 - 12000 rpm |

| max. tool diameter when profiling | 210 mm (8.25”) |

| max. diam. of tool lowered under the table at 90° | 240 mm (9.44”) |

| Spindle moulder available with following diameters: | 30 – 32 - 35 - 40 - 50 mm 3/4" - 1" - 1 1/4" |

Diameter of exhaust outlets: |

|

| Installation requirements | |

| Nominal extraction air consumption | 1050 m3/h (600 CFM) |

| Air exhaust speed | 20 m/s (66 ft/s) |

Electrical requirements ***subject to change; must be verified prior to installation*** | 220 V – 60 Hz – 3 phase – 28 A |

For any questions concerning delivery, please contact eshopsupportus@scmgroup.com

To ensure a clear and hassle-free purchasing experience, below are the weight and dimensions of the packaged machine at the time of delivery:

| Dimensions | ||

| Lenght | in | 78 |

| Width | in | 47 |

| Height | in | 73 |

| Weight | lb | 1176 |

Before completing the purchase, the customer can choose between two delivery options:

1 - Pickup from Our Warehouse (Incoterm EXW - Ex Works)

The machine can be picked up directly from our warehouses. Prior to purchase, verify in which locations this unit is available.

2 - Delivery by Dedicated Freight Carrier (Incoterm DAP - Delivered at Place)

By selecting this option, SCM will entrust the delivery to a specialized freight carrier, ensuring secure transport managed by professionals. The service includes:

- Advance phone notice before delivery

- Hydraulic tail lift for unloading the machine from the truck

Important: Deliveries are made exclusively to the curbside, meaning the machine will be dropped off at the entrance of the building or designated location. Internal transport and positioning inside the premises are not included. If a forklift or other equipment is needed for internal movement, the customer is responsible for arranging these operations.

If the machine is purchased with the installation service, after the order is completed, SCM Service or an authorized center will contact the customer to coordinate: the installation date, the necessary equipment, he required documentation for installation.

SCM Group US is not responsible for any damages, injuries, or losses resulting from improper installation, unsafe or incorrect use of the machine, failure to follow the manufacturer’s guidelines, or any modifications made by the customer or third parties.

Customers who choose to opt out of professional installation assume full responsibility for ensuring that the machine is installed and operated in strict accordance with the provided instructions and safety standards. If you have not received the user manual, please contact us with the machine’s serial number to obtain it before installation and use.

SCM Group US disclaims all liability for any accidents, malfunctions, or consequential damages resulting from non-compliance with these guidelines.

Installation & Warranty Activation

If installation is not included in your purchase and you would like to have the machine installed by our technicians, please contact us.

If SCM installation is not required, you must complete and submit the warranty activation form (VICA) within 10 business days from the machine’s delivery date. The form will be provided with the purchase order confirmation or can be requested by contacting us. Failure to submit the form on time may result in the warranty being voided.

For any further information or assistance, please feel free to contact us.