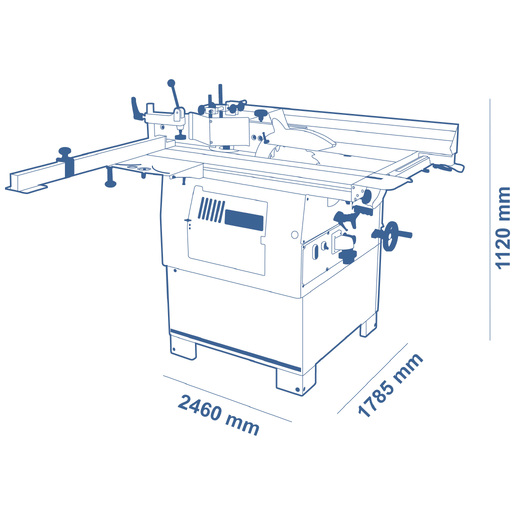

minimax c 26g Universal combined machine

$7,668.42

(Price does not include taxes, shipping and installation)

The c 26g is the universal combined machine with all minimax quality, at the most affordable price.

Maintaining all the quality of the minimax line, it is the ideal machine for demanding hobbyists and crafts woodworking workshops.

A very important aspect that facilitates the work of even the less experienced user, is the maximum ease of use in any working condition, thanks to the quick-locking aluminum fences and the effective feeding system for the planer.

Flexibility is added to ease of use: just think of the multi-speed spindle moulder and its hood with micrometric adjustment for profiling operations. The last aspect that is impossible not to mention is the tilting saw unit, which with its anodized aluminum carriage sliding next to the blade, guarantees high cutting precision.

*Photos may include optional equipment. Please verify availability and compatibility under Product Details and Specs.

The anodized aluminum sliding table slides next to the blade, thus ensuring better cutting precision.

Maximum flexibility when using the cutters, with the spindle moulder unit equipped with various speeds.

Very easy machining on the planer unit thanks to the large dimensioned surface tables.

Thanks to an efficient feed system, the thicknessing unit can process wood up to 200 mm thick.

SCM Thundercut App for tablet: cutting optimizer and sequencer even for less experienced operators.

- Tilting saw unit for greater versatility of the machine, it allows to carry out different types of machining, without limitation to creativity

- Saw unit raising and tilting using convenient hand-wheels which guarantees maximum setting ease between different processes

- The squaring frame ensures excellent work piece support, to ensure greater safety and precision

- Extruded aluminum fences with support and rapid locking guarantee maximum practicality.

- The surfacing table opens towards the inside of the machine guarantees excellent ergonomics, allowing the operator to move easily and without hindrance

- The "Tersa" cutterblock with 3 knives with rapid locking ensures a very rapid set up.ith micrometric

- The spindle moulder fence with micrometric adjustment is very useful for profiling jobs.

- Wheels for an easy machine movement

*Do not include power cable

MACHINE CONFIGURATION

(Options and accessories included with this machine)

- Squaring frame

- Wheels for machine movement

- "Tersa" cutterblock Ø 62 mm with 3 knives with rapid locking system

- 3 single-phase motors 1,8kW (2,5hp) 50Hz - 2,2kW (3hp) 60Hz

- Spindle moulder shaft of 1 1/4"

- Locking by countersunk socket screw

| TECHNICAL FEATURES | ||

| Planer: | ||

| Useful working width | [mm] | 260 |

| Cutter block diameter | [mm] | 62 |

| Maximum stock removal | [mm] | 3 |

| Surfacing tables total length | [mm] | 1040 |

| Thicknessing table dimensions | [mm] | 260 x 450 |

| Feed speed on thicknesser | [m/min] | gen-00 |

| Minimum ÷ maximum working height on thicknesser | [mm] | 3 ÷ 200 |

| Circular saw: | ||

| Cast iron saw-spindle moulder worktable dimensions | [mm] | 1024 x 224 |

| Blade tilting | 90° ÷ 45° | |

| Maximum saw blade diameter | [mm] | 250 |

| Maximum saw blade projection from table at 90°/45° | [mm] | 75/60 |

| Maximum squaring stroke | [mm] | 1200 |

| Cutting width on parallel fence | [mm] | 500 |

| Spindle Moulder: | ||

| Spindle diameter | [mm] | 1 1/4" |

| Useful spindle length | [mm] | 75 |

| Spindle moulder speed | [rpm] | 6000/8500 |

| Maximum tool diameter when profiling | [mm] | 160 |

| Maximum tool diameter lowered under the table at 90° | [mm] | 145 |

| Other technical features: | ||

| Single-phase motors | 1,8kW (2,5hp) 60Hz | |

| Exhaust hoods diameter | [mm] | 120 |

| MINIMUM INSTALLATION REQUIREMENTS | ||

| Section of electrical cable | [mm2] | 4 |

| Power absorption | [A] | 12 |

| Voltage - frequency | 230V - 60Hz |